Have you ever wanted to put a dump bed it on your truck?

No, you say, well it’s nice to know people with self-control. Stick around, I could use rational people in my life.

So it all started one day, when I had a midlife crisis and realized that my Chevy HHR couldn’t haul dirt worth shit. This really hit home for me as I was enjoying my leisurely stroll through the local auction where Los Angeles dumped all their old trucks.

Wanting a four-wheel-drive, and refusing to buy a truck with a 6.0 Ford diesel, the pickins were pretty slim. When I found this Chevy 3500 Silverado with a Duramax engine and four-wheel-drive, I knew I was staring down the most elusive unicorn I’d ever seen. Okay, a little dramatic, but have you ever tried to find a four-wheel-drive diesel truck at a government auction in Los Angeles?

This truck came with an amazing, yet completely worthless for my purposes, utility bed. Anyhow, long story short, craigslist to the rescue and I sold it off for a pretty penny.

Fast-forward, the bed removed and a bare chassis to work with, it was time to deal with the first problem. How do I secure the fuel filler tubes that there were no longer supported by the utility bed? I actually received my zip tie technician certificate for this one. ...and later hose clamp certification.

On to the brackets that came with the dump mechanism. I’d have to figure how to mount them to the chassis. Into the mill they go.

It turns out, they needed to go exactly where the overload leaf spring stops were located. Not wanting to share their prized position, I convinced them to be a team player, and bribed them with some longer bolts.

Time for a little test fitting. It looks like the hydraulic pump and reservoir with fit right between the frame rails. A couple feet of duct tape, and I'm good to go.

That problematic rear end. I cut the back of the frame rail at an angle so the dump bed pivot would not hit.

Setting the dump mechanism in place with the precision of drunken sailor I was starting to gain the false hope that this was going to be easy.

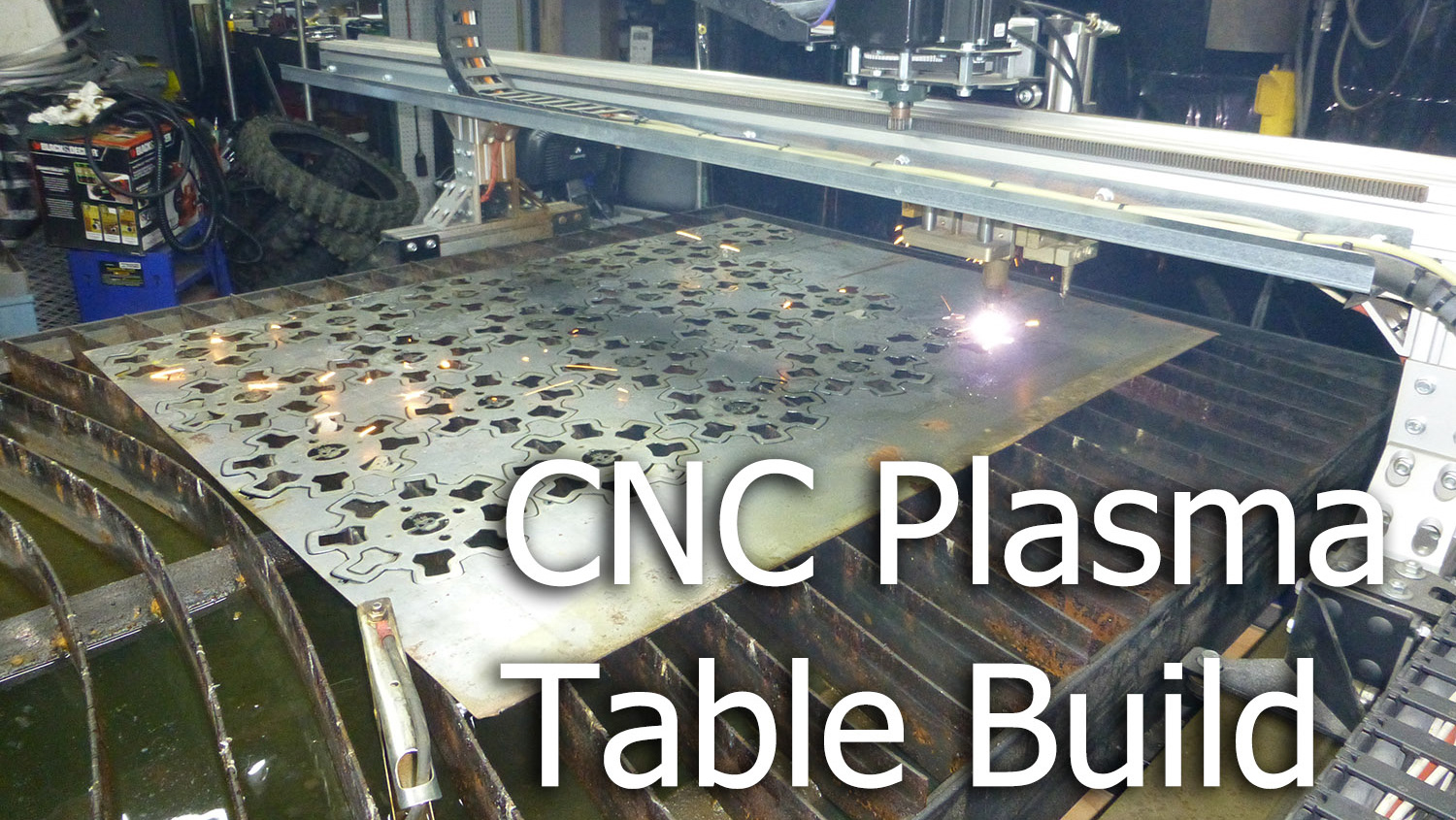

With the dump mechanism precariously located, I turned my attention to the rear pivots. Thanks to my precision like plasma cutter actions, emulating a surgeon with a hatchet, the hinges fit right in place.

I fabricated a rear support for the lift mechanism to rest on. At this point I could use a nap myself.

Bolted in place, I can now have my clamp back. I really need to buy more than one of those.

Needing to feel a sense of accomplishment, I hooked up the plumbing for the hydraulic pump.

Now, with my zip tie certification, I had the confidence required to secure the wires and hoses the fancy way.

The dump bed kit came with two individual pins for the rear hinge mechanism. I was not comfortable with this method, as I felt it put more torque on the assembly than necessary given my setup.

After attempting to karate chop the pieces of steel to the correct length, it quickly occurred to me I should not attempt to instruct other people. Luckily, my bandsaw was more adequately equipped for the task.

You can see where I replaced the individual pins with a solid bar that stretched from end-to-end.

The rear hinges, also being asked to shoulder a heavy load were rewarded with a piece of box steel to rest on.

Spaced apart more than ideal, I had to work with the flatbed Craigslist bestowed onto me.

When a clearer mind prevailed, I decide to forgo the duct tape, and I made a custom steel plate to mount the hydraulic pump and reservoir to the chassis. In the spirit of not catching my truck on fire, I even added a heat shield to protect the hydraulic reservoir from the hot exhaust system.

With my fragile ego still intact, I ran the wiring, and nothing caught on fire.

After wiring up the hand controller, it occurred to me that someone had built it completely upside down.

This may be more than I can handle.

Unwilling to be deterred, I filled the reservoir with hydraulic fluid and pushed the corresponding button for the vertical motion that I desired. To my amazement, it sprung into action and shot into the air like a rabid dog after a squirrel. With all the excitement, the bubble fairies joined in the celebration.

Even with all the excitement, I knew the victory would be short-lived if I did not give the electronics the protection they desire. After a liberal dosing of waterproofing grease, it should have a long prosperous life.

Now I’d have to put on my big boy pants. It was time to mate the bed to the dump mechanism. This bed, was a $500 craigslist special and was not a perfect fit, but beggars can’t be choosy.

There’s a time in every project, where you have to take a break, relax and play a game. The game of the night was removing the frozen nut. I played this game more often when living in the Midwest, but it always brings back those childhood memories when ever I get the opportunity.

After I tried all the standard method, it was time to get creative. Using a ratchet strap to pull a pipe wrench kind of felt like performance art.

Working by myself, I did not have any way to properly secure a wrench to the bottom nut. Even with an extreme effort of a creative but vulgar display of clamp-on-clamp abuse. I still couldn’t break the nut loose.

With what I thought was a moment of engineering clarity, I welded a nut onto the top of the ball and tried to go to town with a 1 inch impact gun. Even calling in the biggest guns, and the cavalry giving everything it had to offer, the battle ended in failure.

The story did have a happy ending, but possibly not in the way you would expect.

Even down the road of total failure, you sometimes stumble upon the occasional success. After all, even a blind pig occasionally finds a truffle. With the grinder a compete failure from the top, it succeeded from the bottom. It took no mercy and cut right through the nut with a level of relentlessness that would make Genghis Khan proud.

Even with the forklift reporting for duty, I knew this would be no easy task. Even my simple mind was able to easily understand the problem of placing a 9 foot bed with 42 inch forks.

However, before we even go down the dark road before us, there was chicanery to be done. The rear bumper had to be viciously removed from the bed so it can be welded directly to the chassis of the truck.

I pulled out my tape measure to give the appearance that I know what I’m doing. However, I was able to conclude that the bed needs to attach here. I also concluded that the bed needs to sit half an inch higher than this mounting bracket allows.

Sticking on the theme of being a cheap ass. I cut some strips of metal off an old baseplate

Good enough for government work.

Have you ever had one of those moments where he had a really bad idea, but nonetheless it was your only idea. Yes, this was one of those moments.

After a lot of nail-biting and one strap deciding to go rogue, I decided to open my eyes and stop biting my nails so I could put my hands back on the controls. It turns out that I was winning against all odds. The bed was almost in position and I pretended that I knew it would work all long.

A little more repositioning was required, but success was now in view only moderately off in the distance.

Back to the strips of metal I made earlier, it turns out that I actually knew what I was doing.

Not out of the woods yet, I did have to notch the back of the bed to fit over the pivot brackets.

Notched and positioned, locked and loaded, it was ready to be welded in place.

A few more tacks, and it was time for the test flight. No pressure…

Is that right?

All the pivots, appear to be doing the pivoty things they are supposed to. Time for the final welding.

Prettier than a new set of snow tires in the middle of a blizzard. If you ever need pickup lines, I’ve got your back.

So, apparently am supposed to put this safety thing on so you can prop up the bed while you’re working under it and not have it fall on you. Next thing you know, they will tell us not to stick forks in outlets. What’s his world coming to?

Okay mom, happy?

Years later, I really need to change out those 12-year-old truck tires.

With the dump bed completed, and a couple years past, I still haven’t dealt with the biggest problem that this truck has. You can only a polish a turd so much, but at the end of the day I have to admit, this truck is yellow. And not just any yellow, it is school bus yellow. But on a bright note, the chance of it staying yellow is about as good as the chance of finding an honest politician. Stay tuned!