I was playing around with a bunker concept that would be made out of two reenforced shipping containers flipped upside down and a slab being placed over the top.

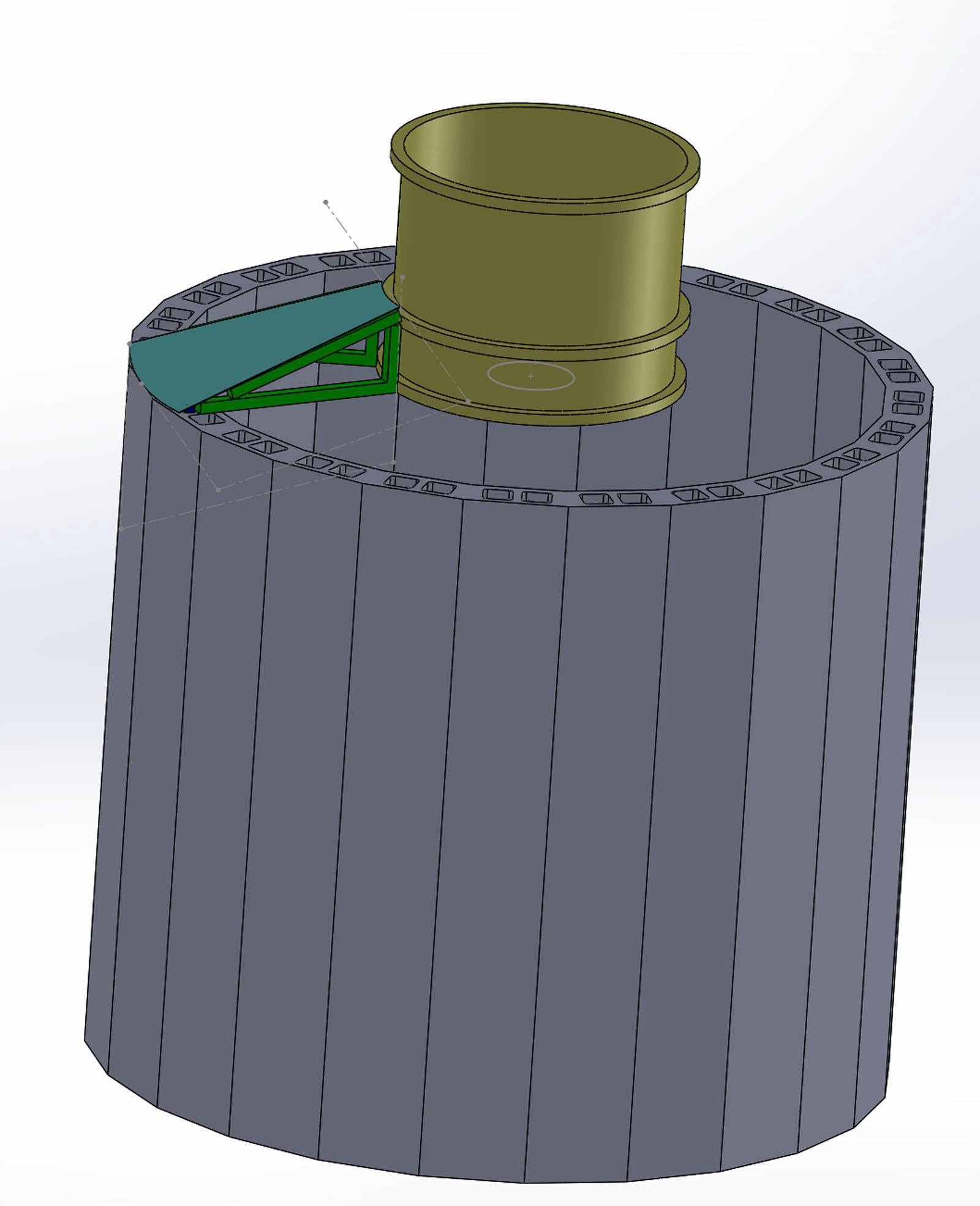

This is a simple root cellar design made from 8” x 16” cinderblocks.

An air powered forging hammer. I currently have the parts for this but have not yet completed it.

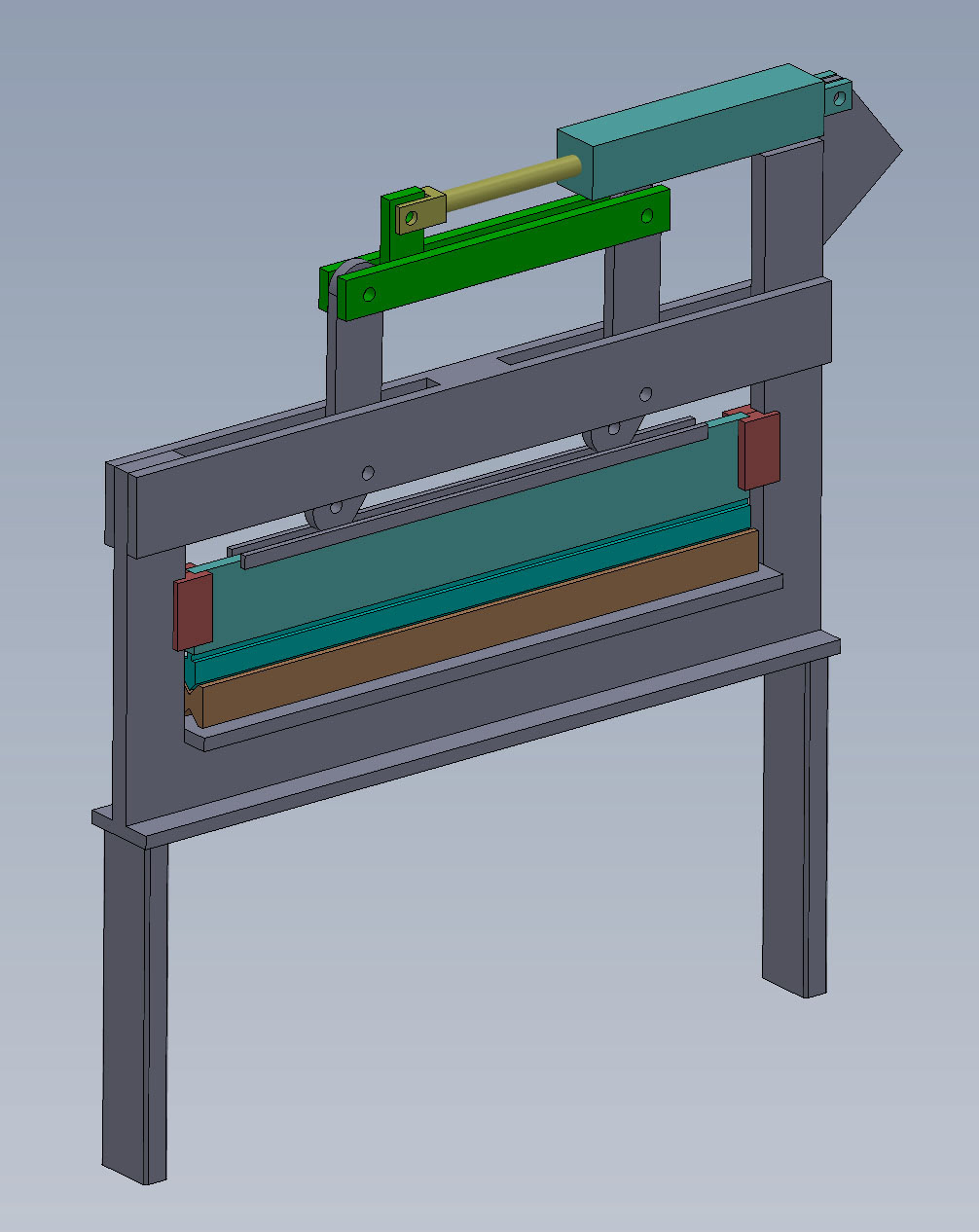

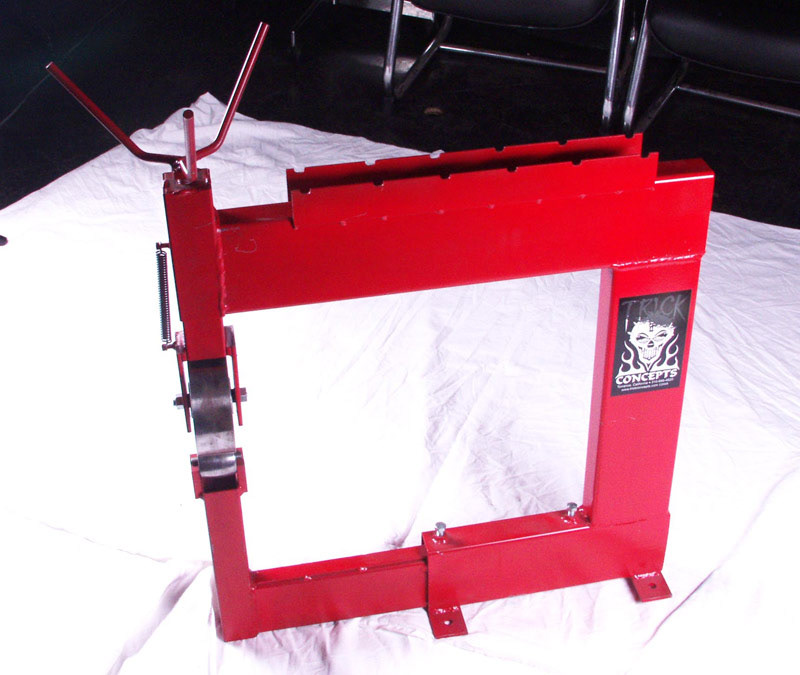

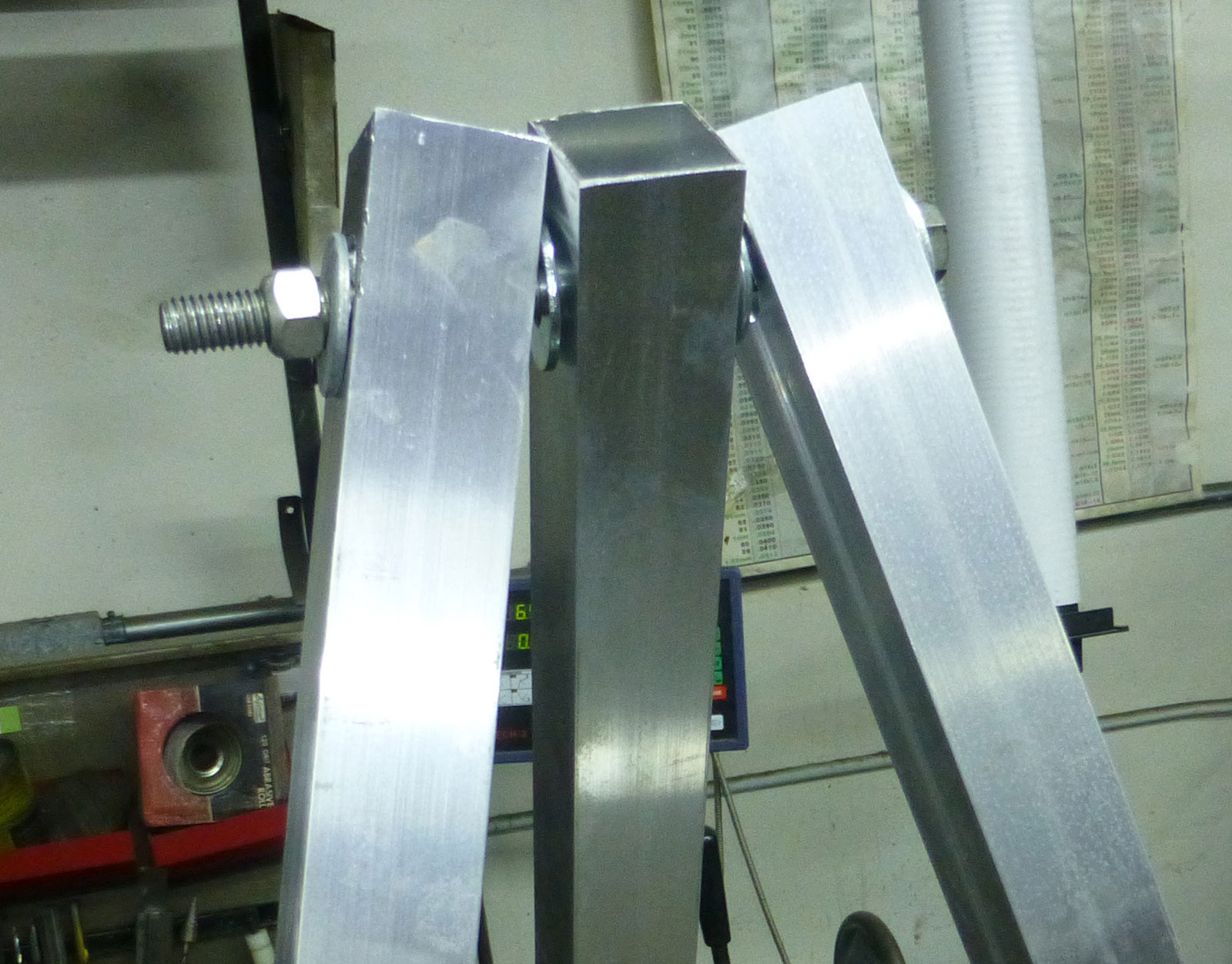

This is a simple break press design I made, but ended up not building it because I purchased a break press.

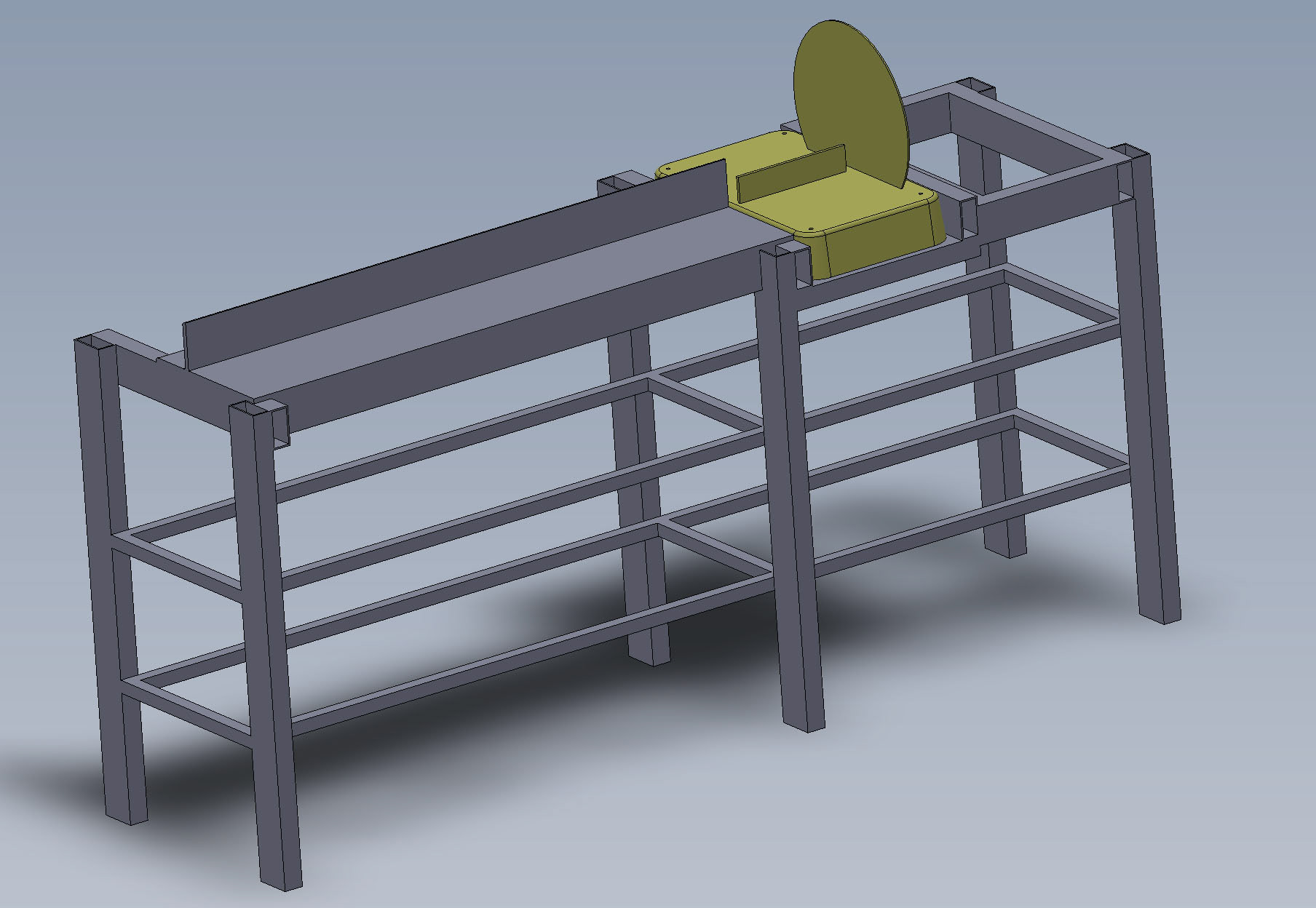

This is a steel chop saw table that I used until I purchased a cold saw.

This cabinet is for housing a small CNC router and dust collection system. This design was completely built.

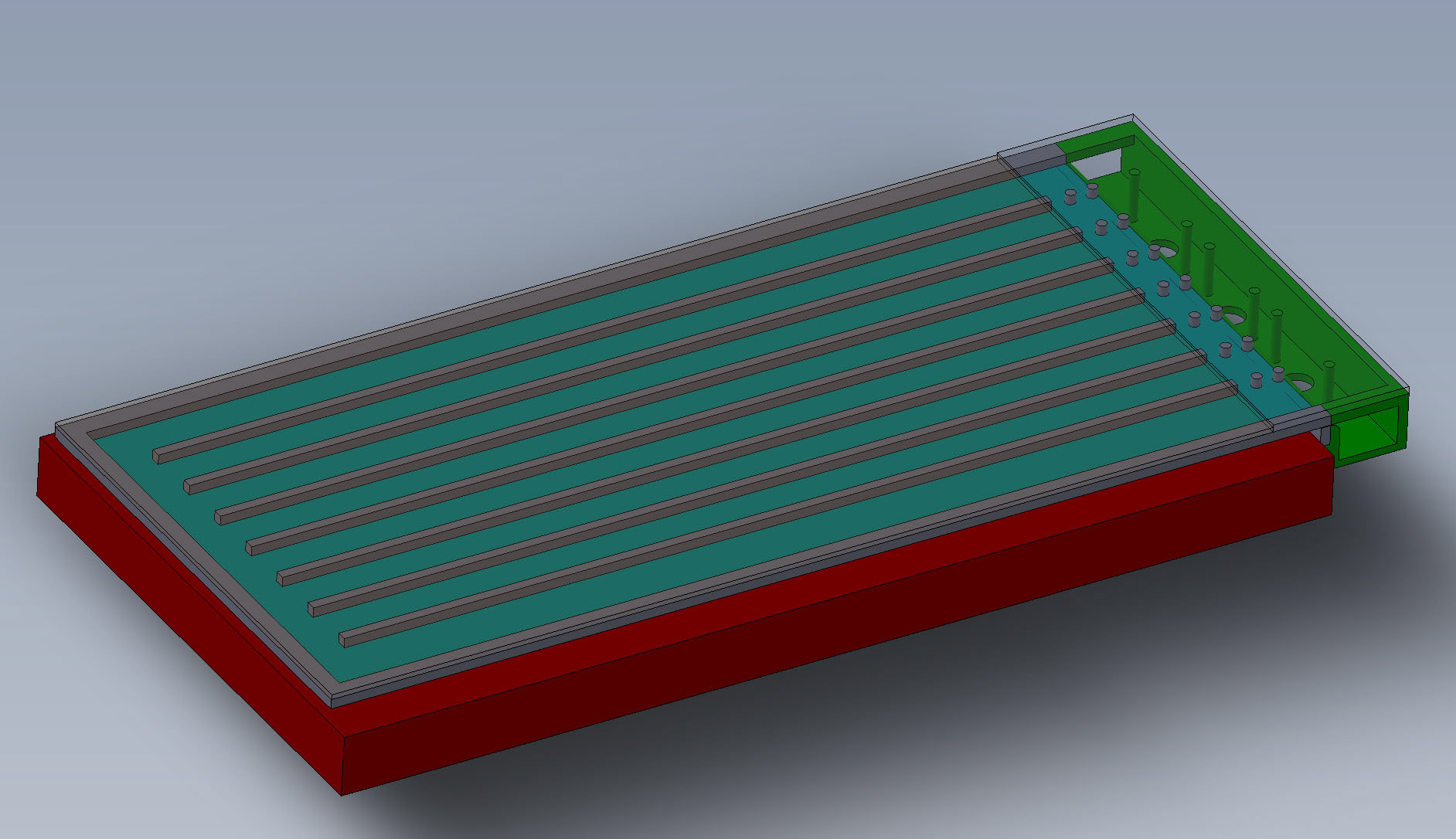

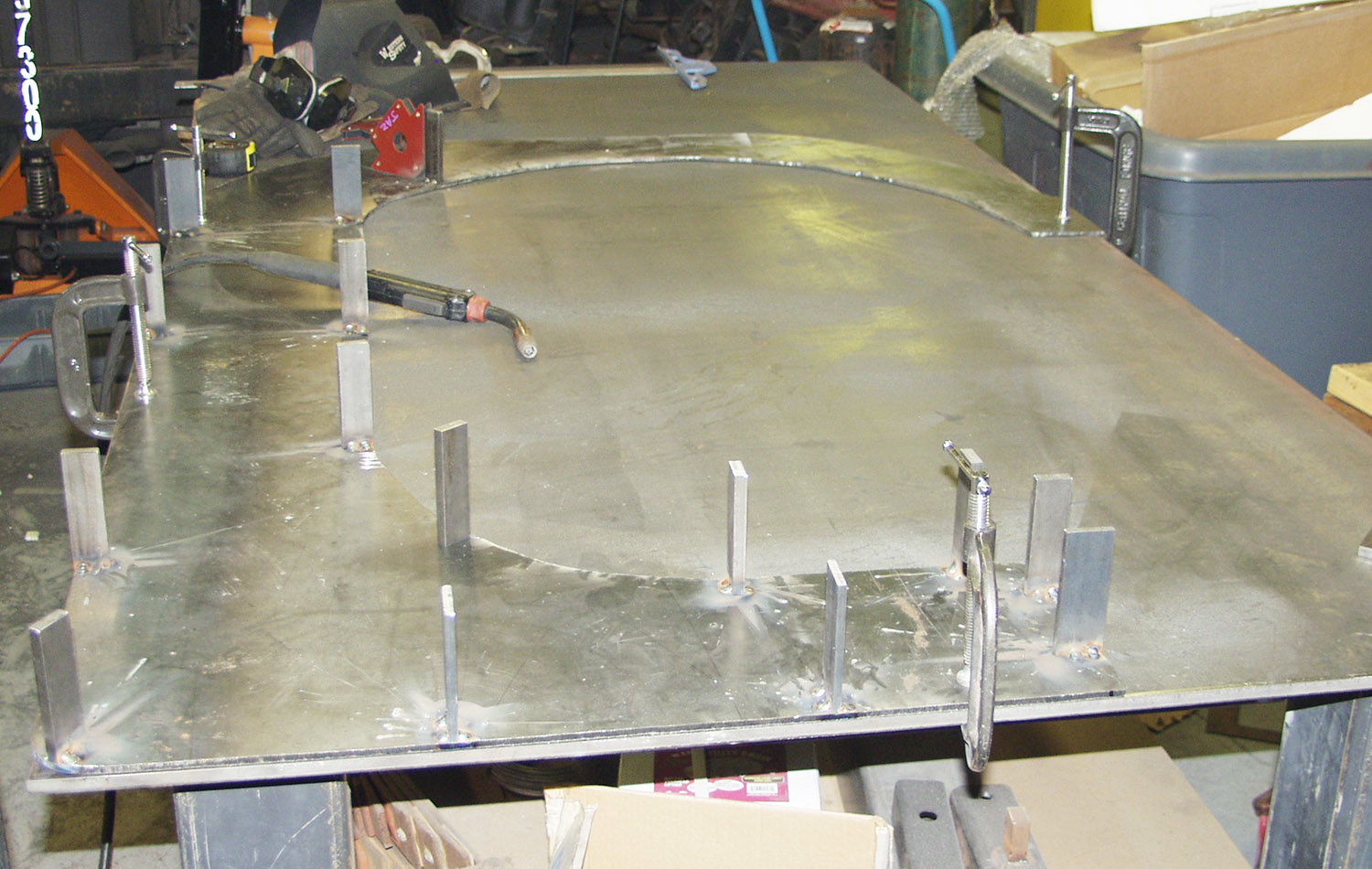

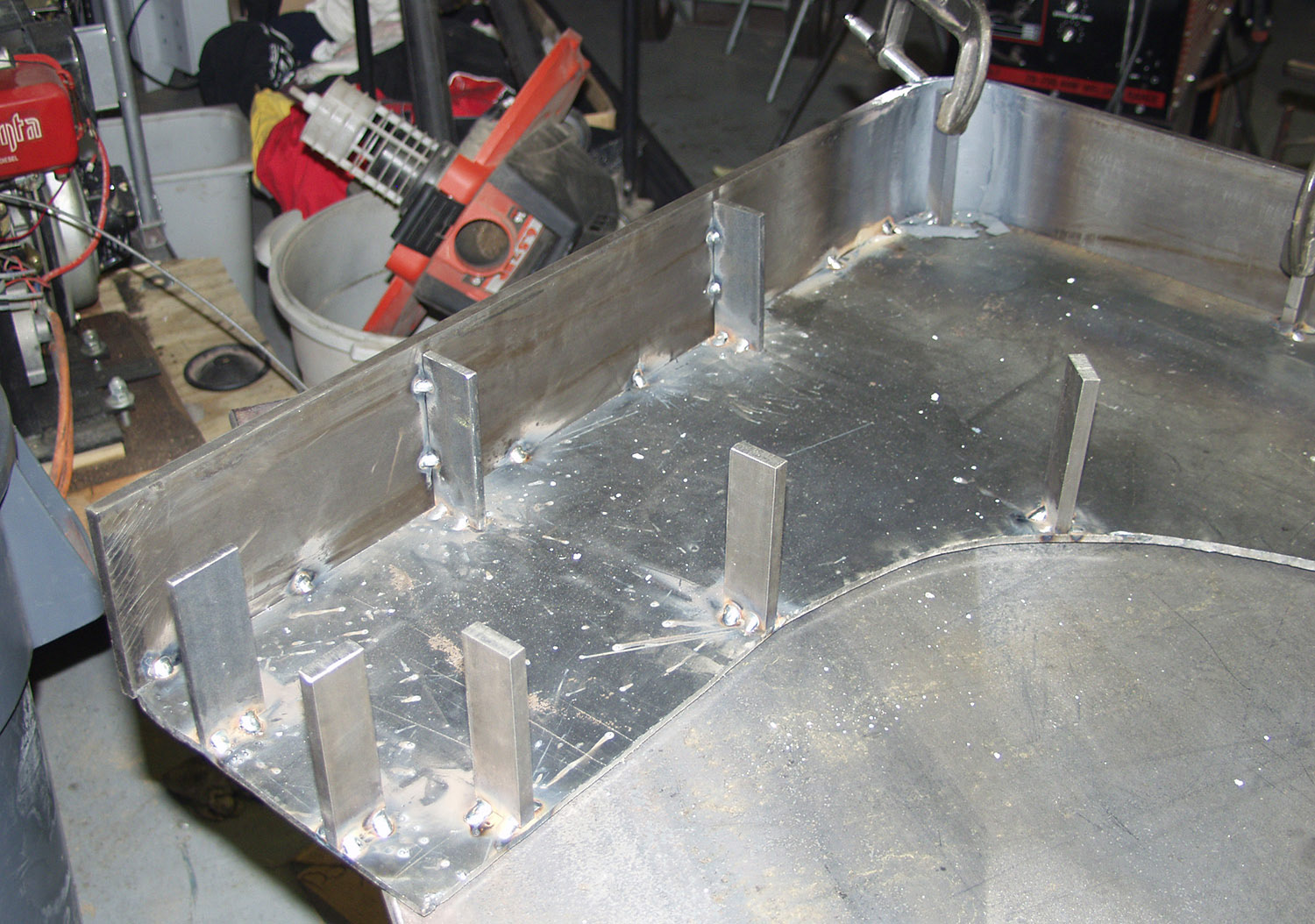

This is a concept I created for vacuum table for CNC router.

This concept is a drum sander that uses Velcro backed sandpaper attached a cylinder. I’m partway done building this.

This is a basic concept for a hydraulic press.

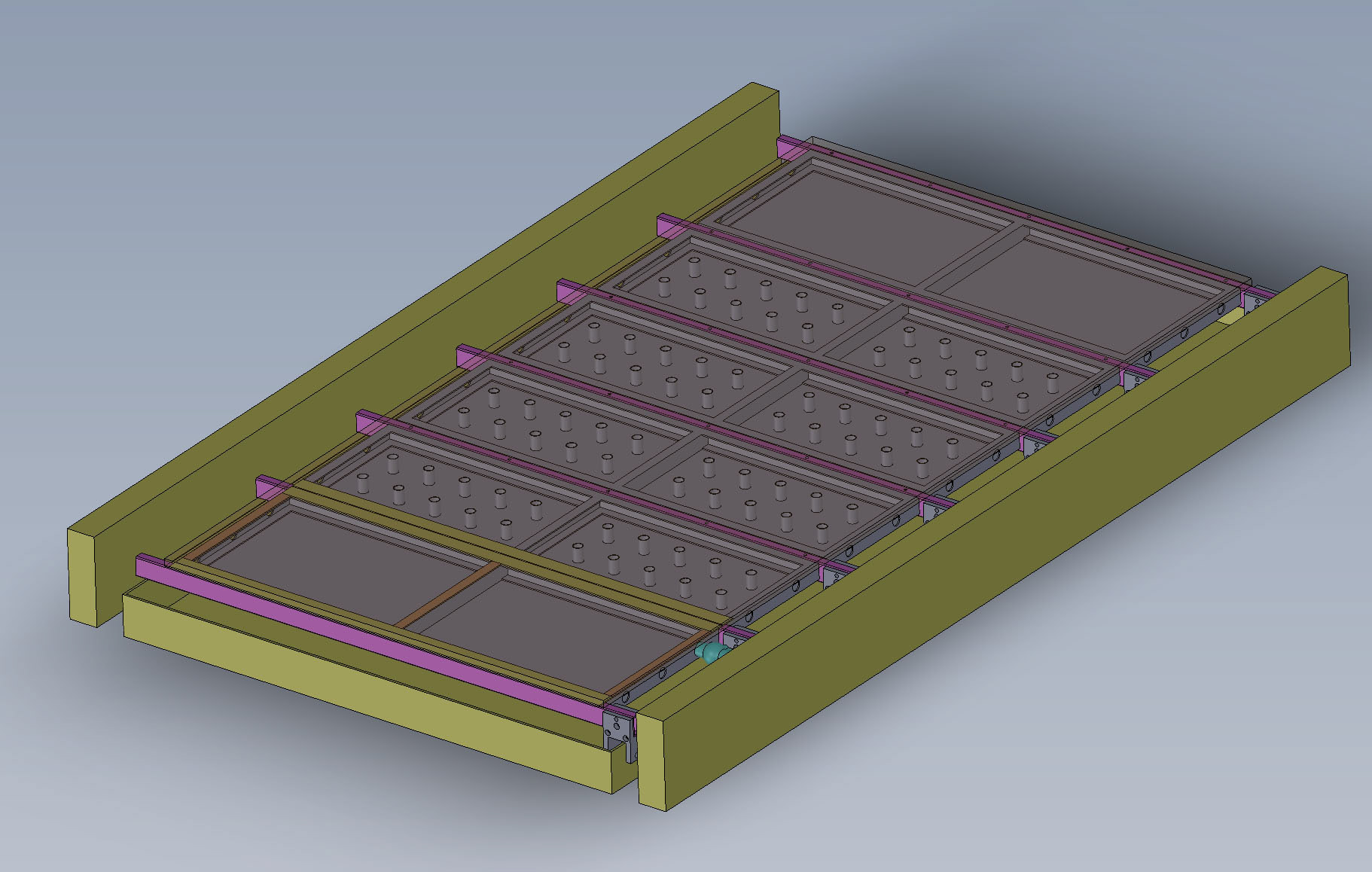

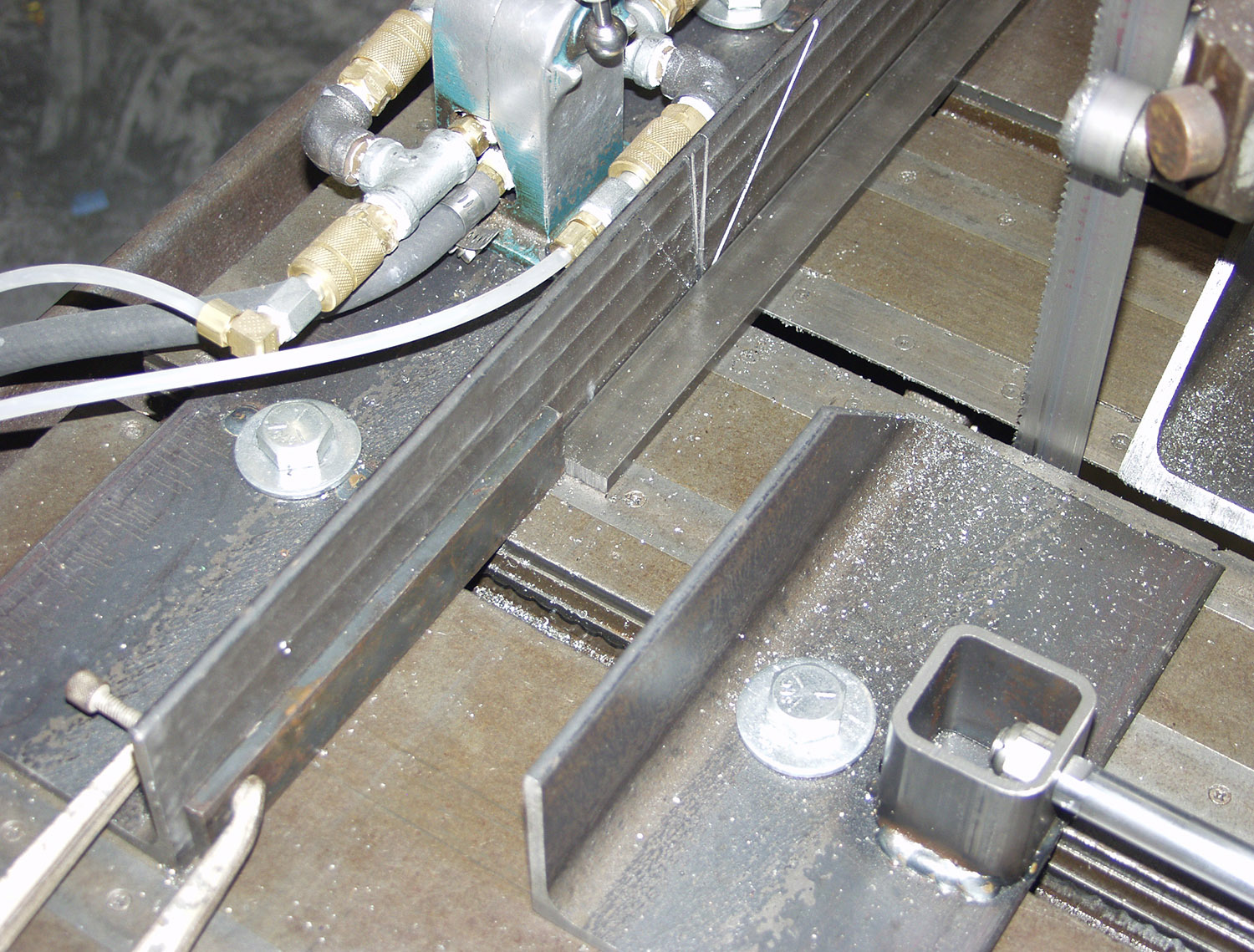

This is a modular system for a CNC router vacuum table. Only the sections that are needed at any given time would be supplied vacuum. Initially, I was going to use this on my CNC plasma table, but I decided that I wanted to have a dedicated CNC router table so I did not have to use the plasma table for this purpose

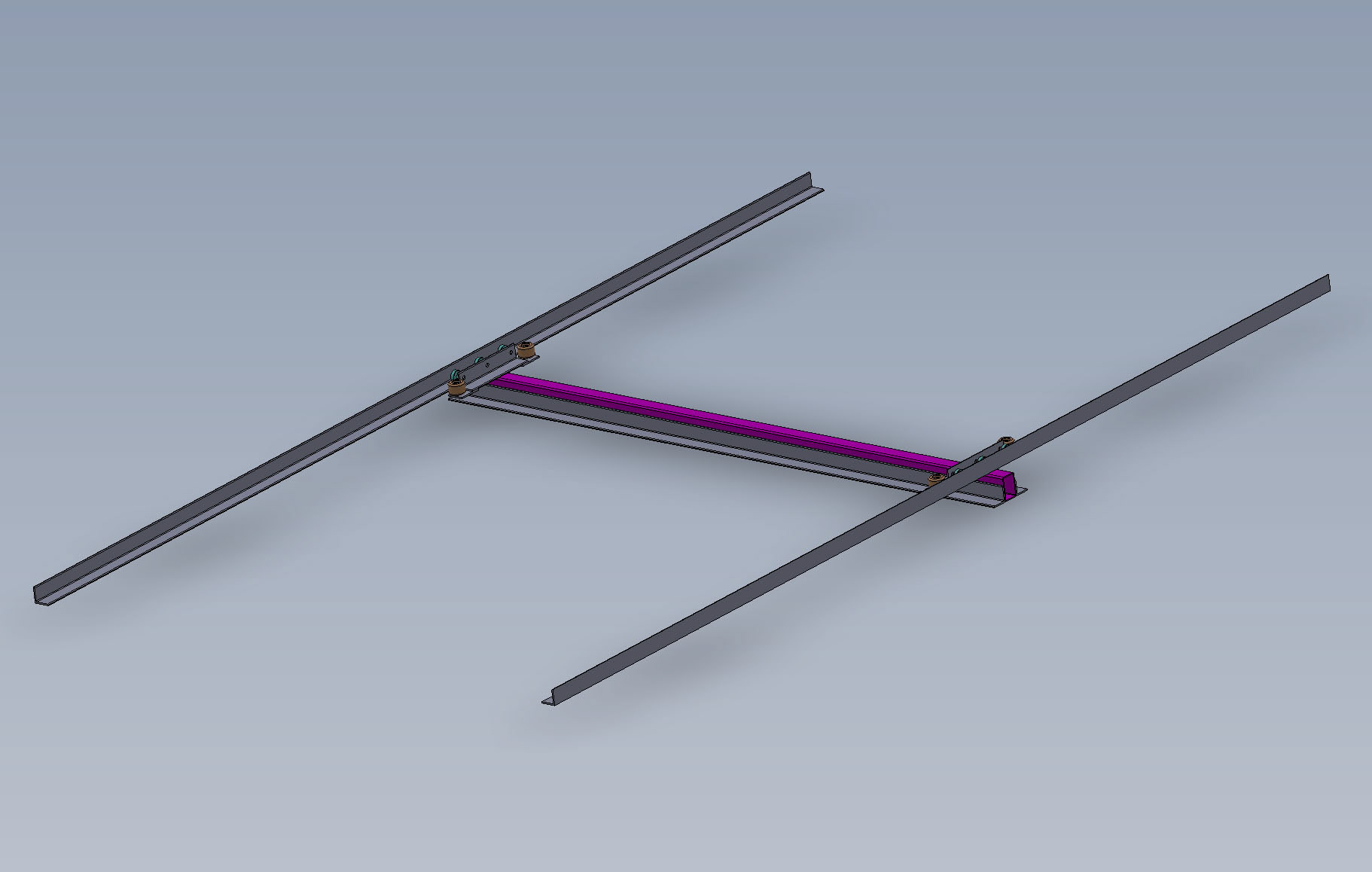

This is the gantry that mounts above my plasma table for loading metal.

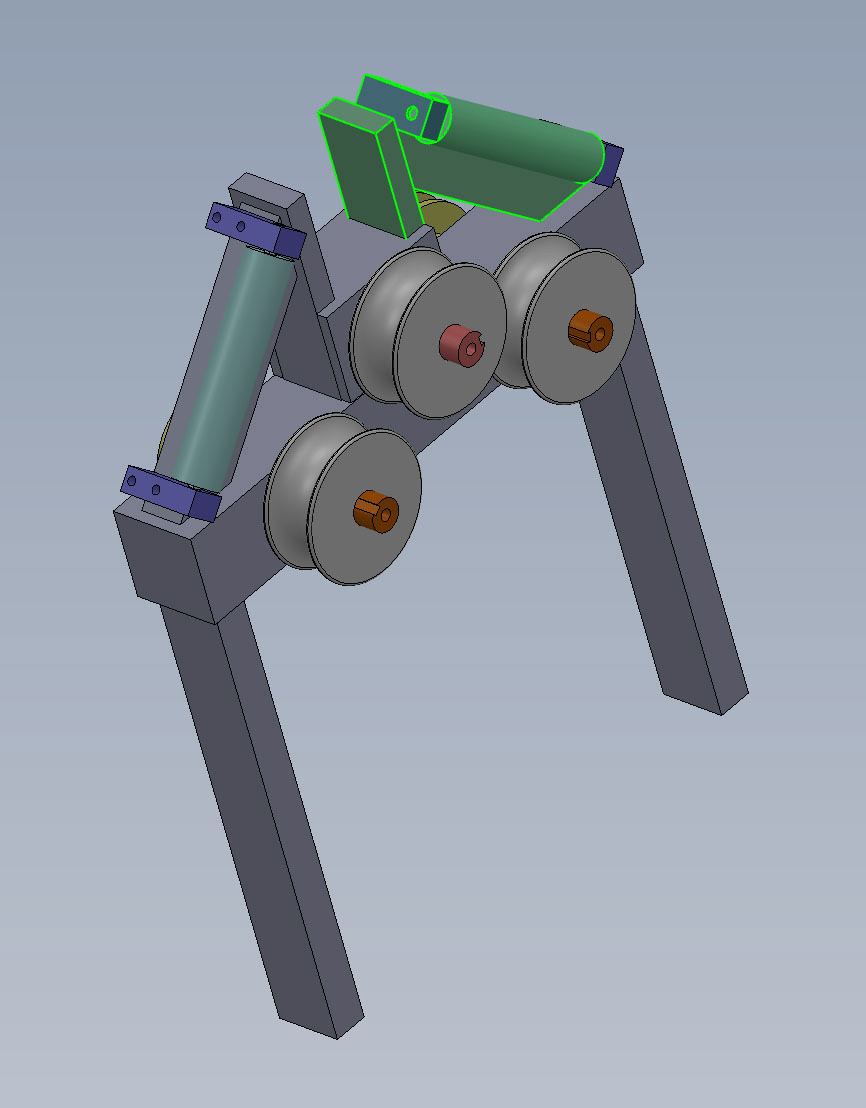

A design for a role former. The shafts ride on truck tapered roller bearings to keep the cost down

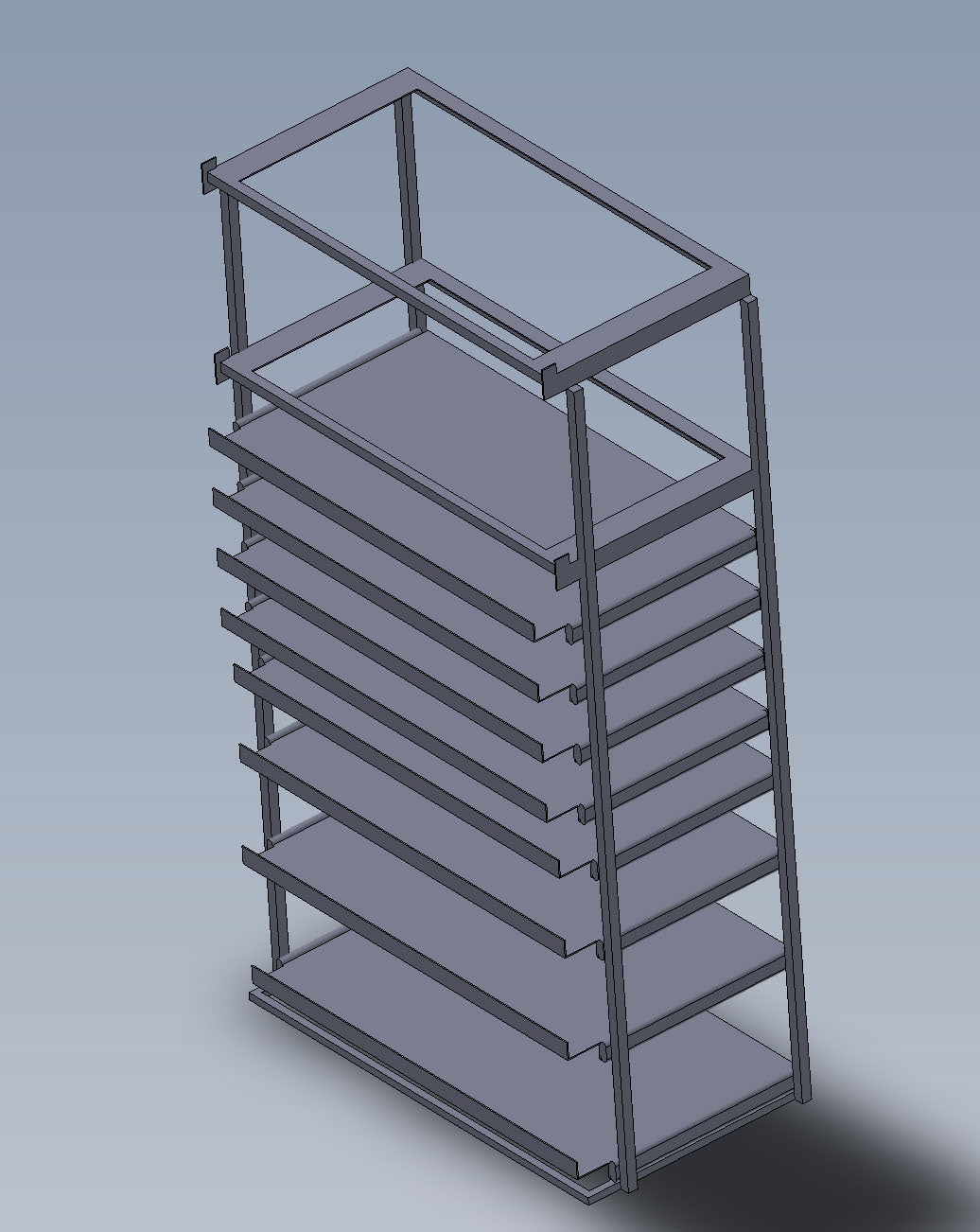

This is a shelving system were all of the drawers pullout for easy access. I built 18 of these units.

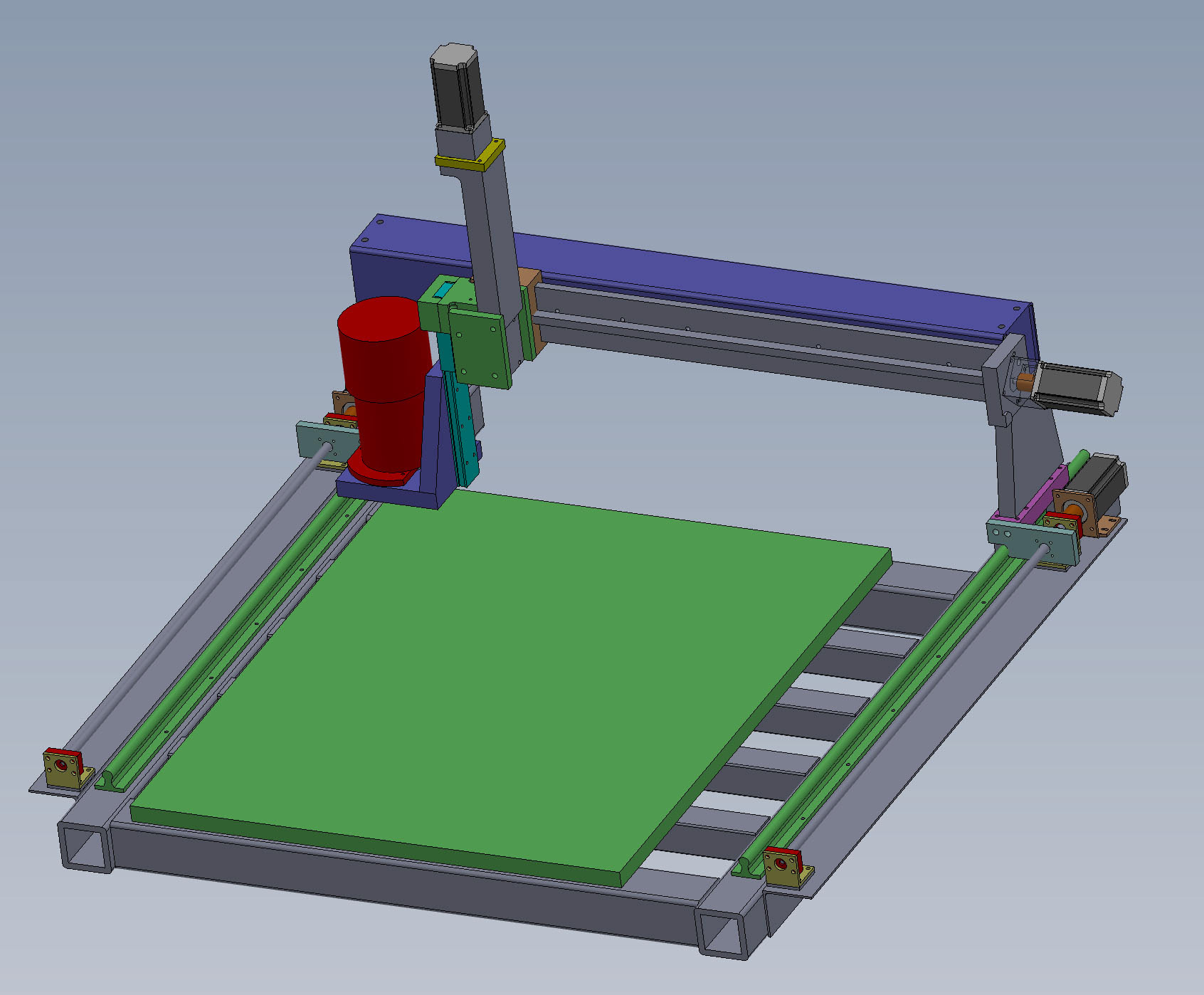

A CNC router design. I built this complete unit from scratch and is operational.

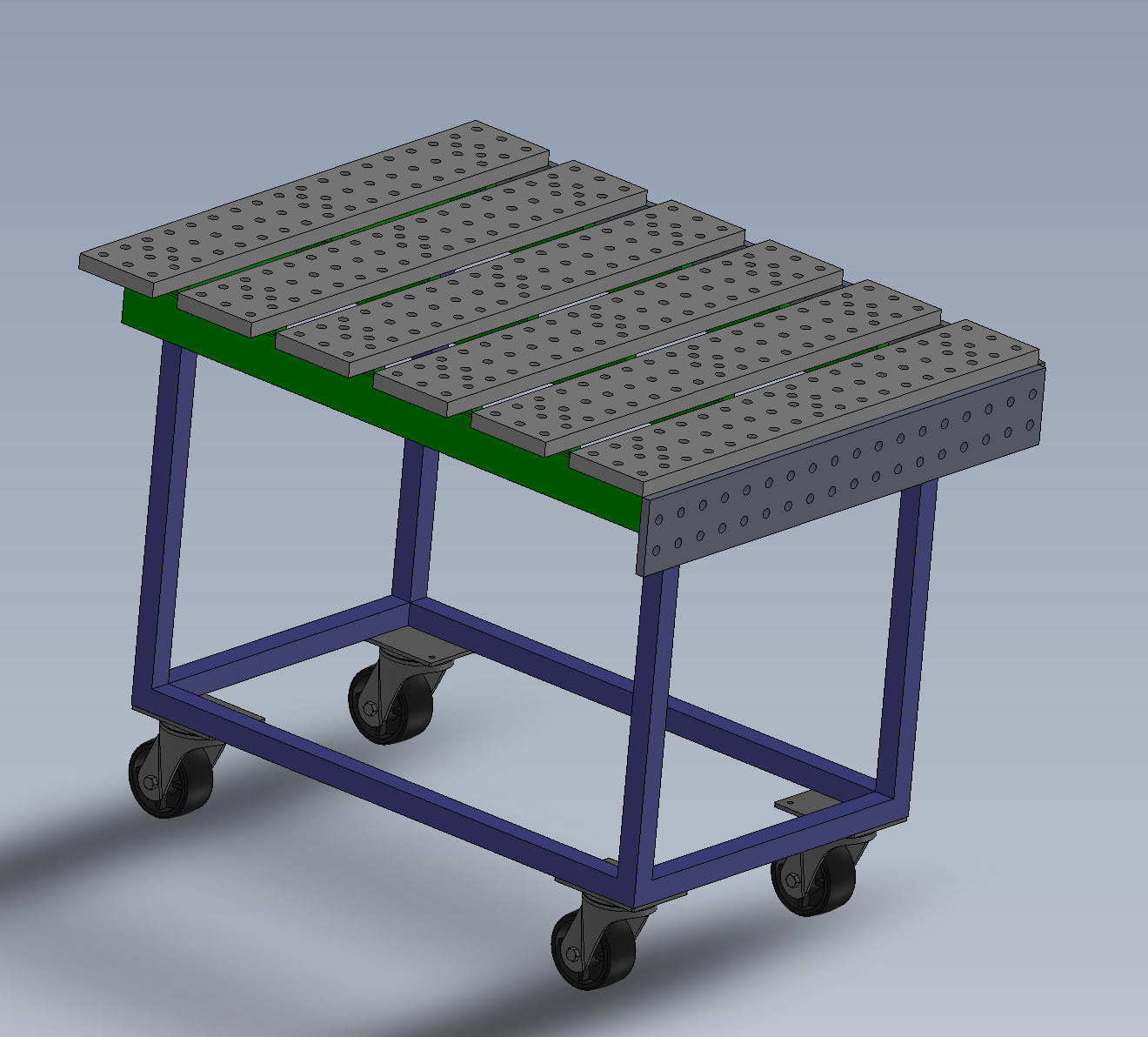

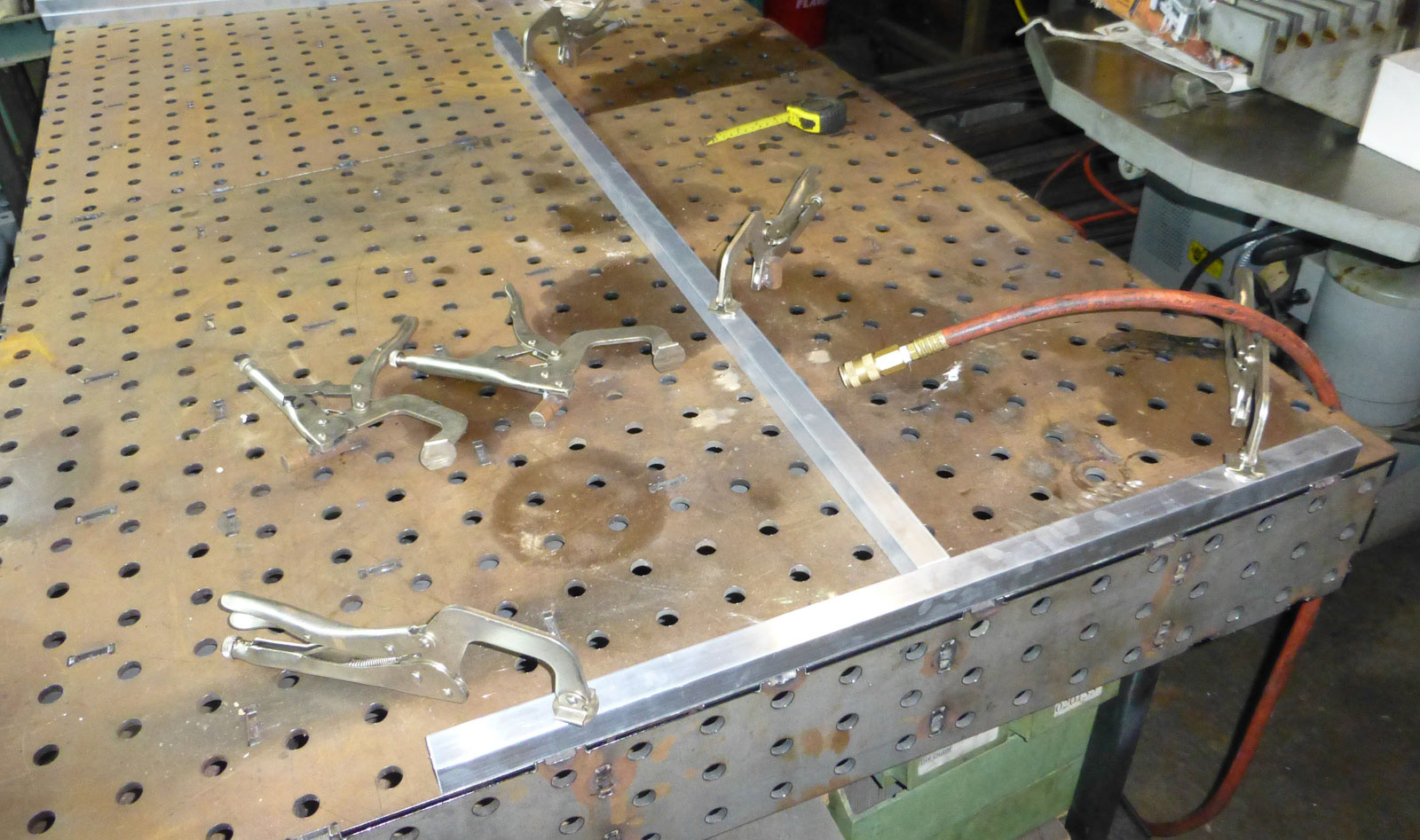

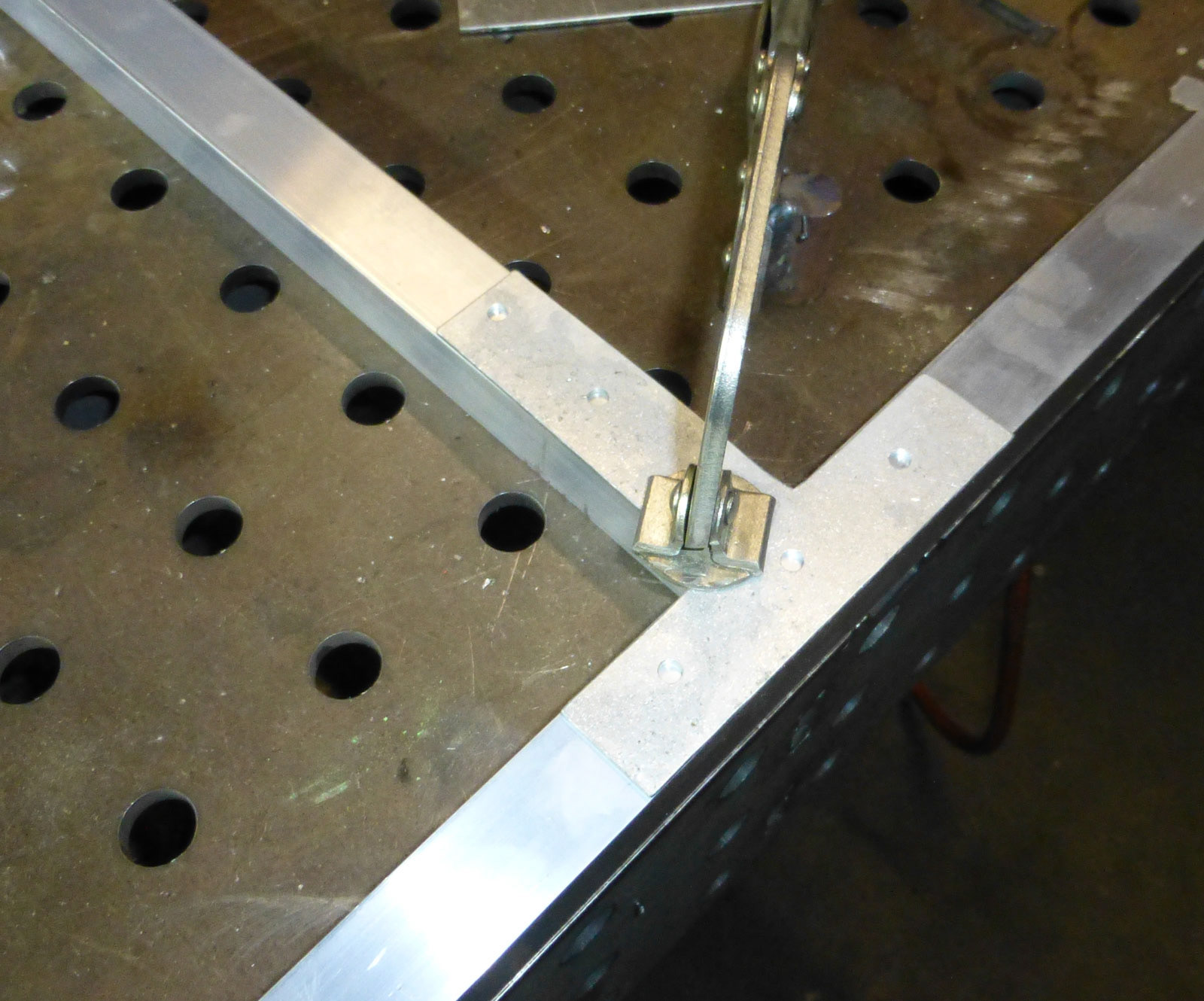

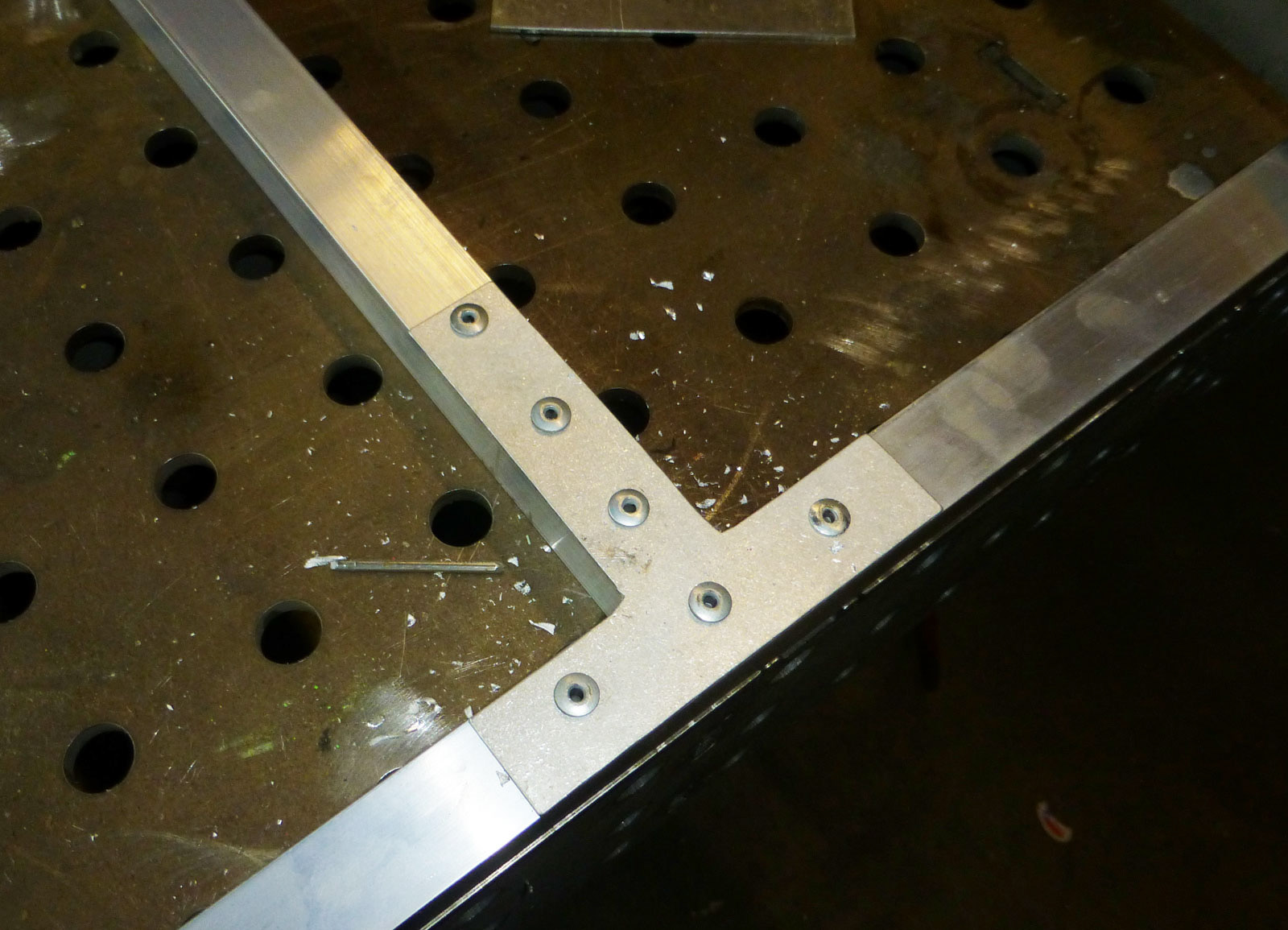

This is a design for welding tables I was going to make, however I did not have a good way to drill that many 5/8 inch holes so I ended up purchasing and building a laser cut table kit.

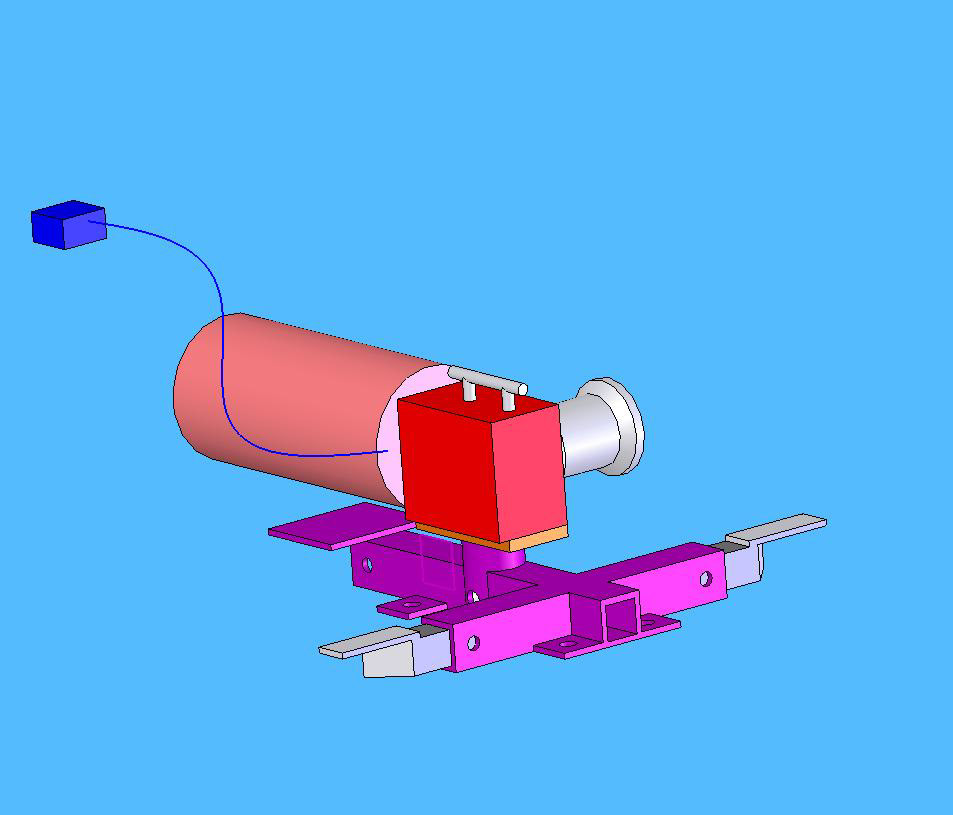

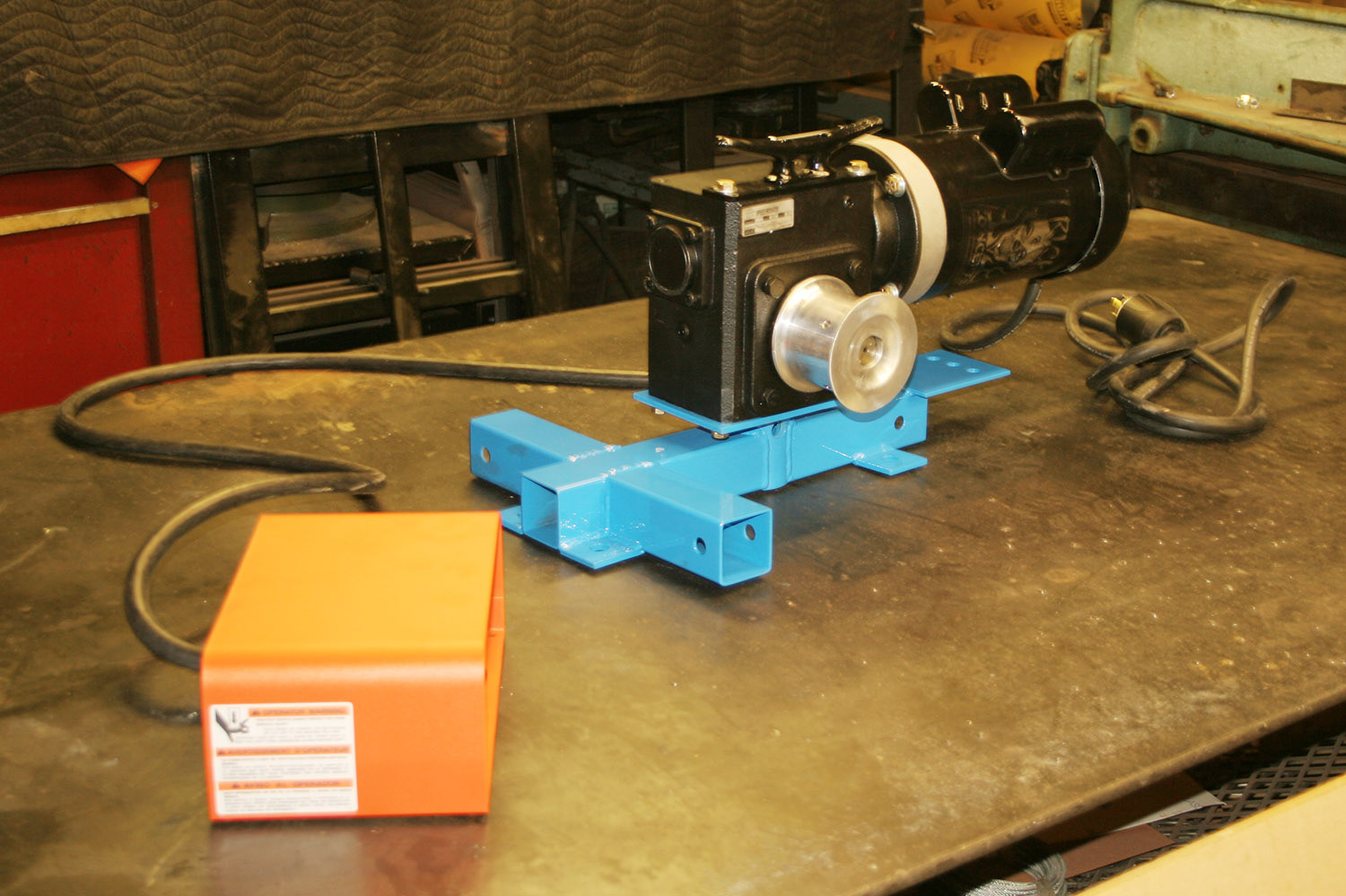

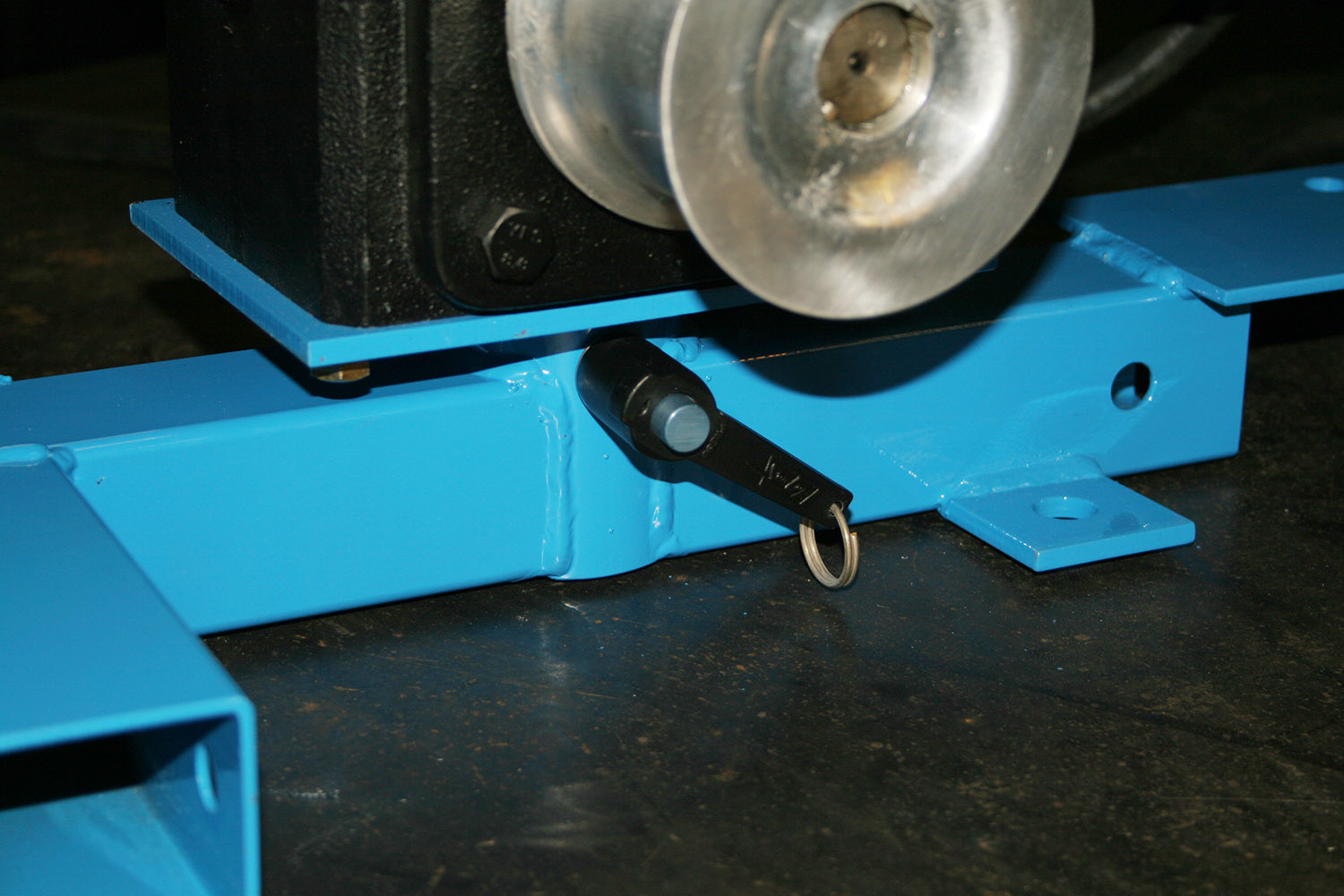

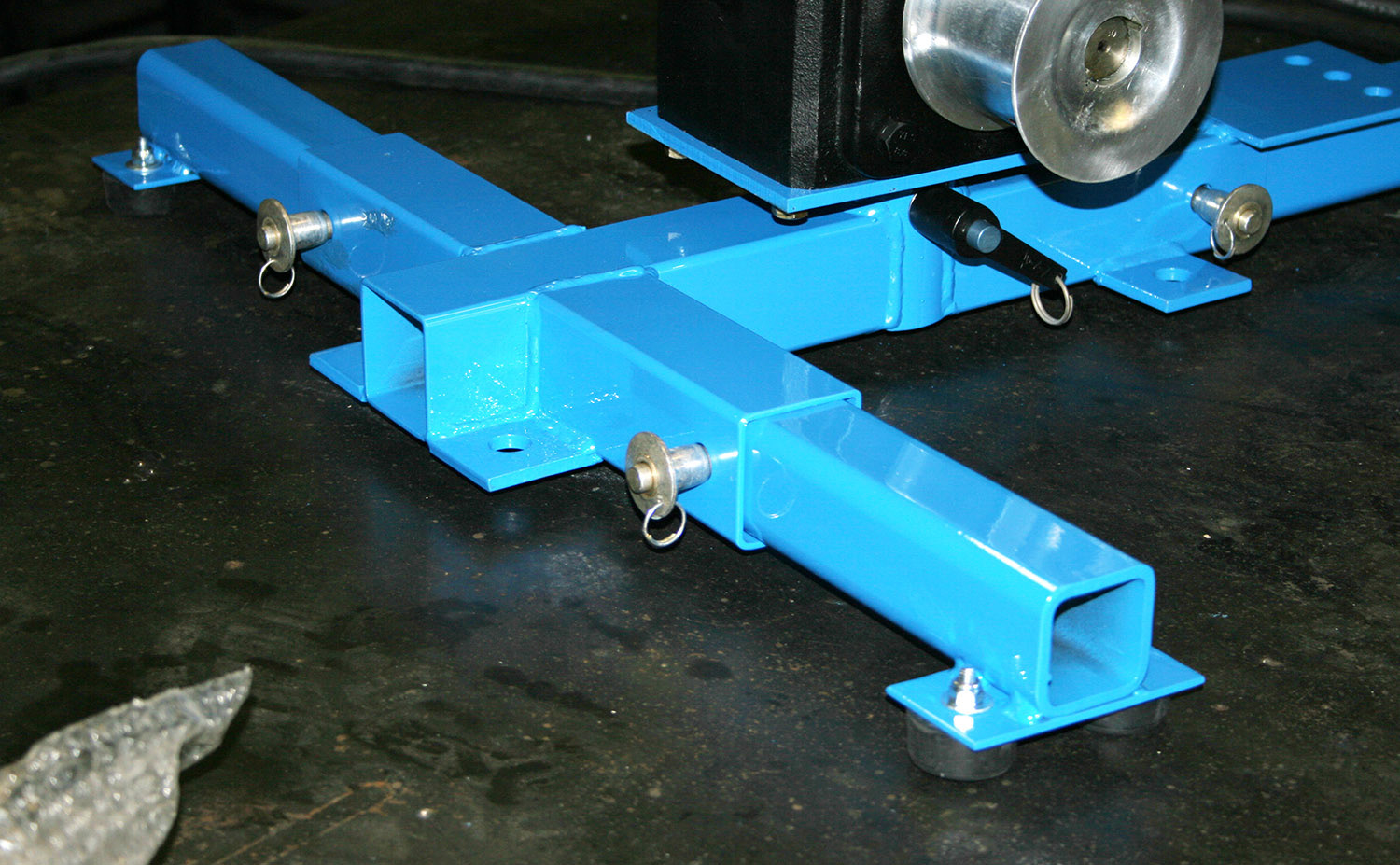

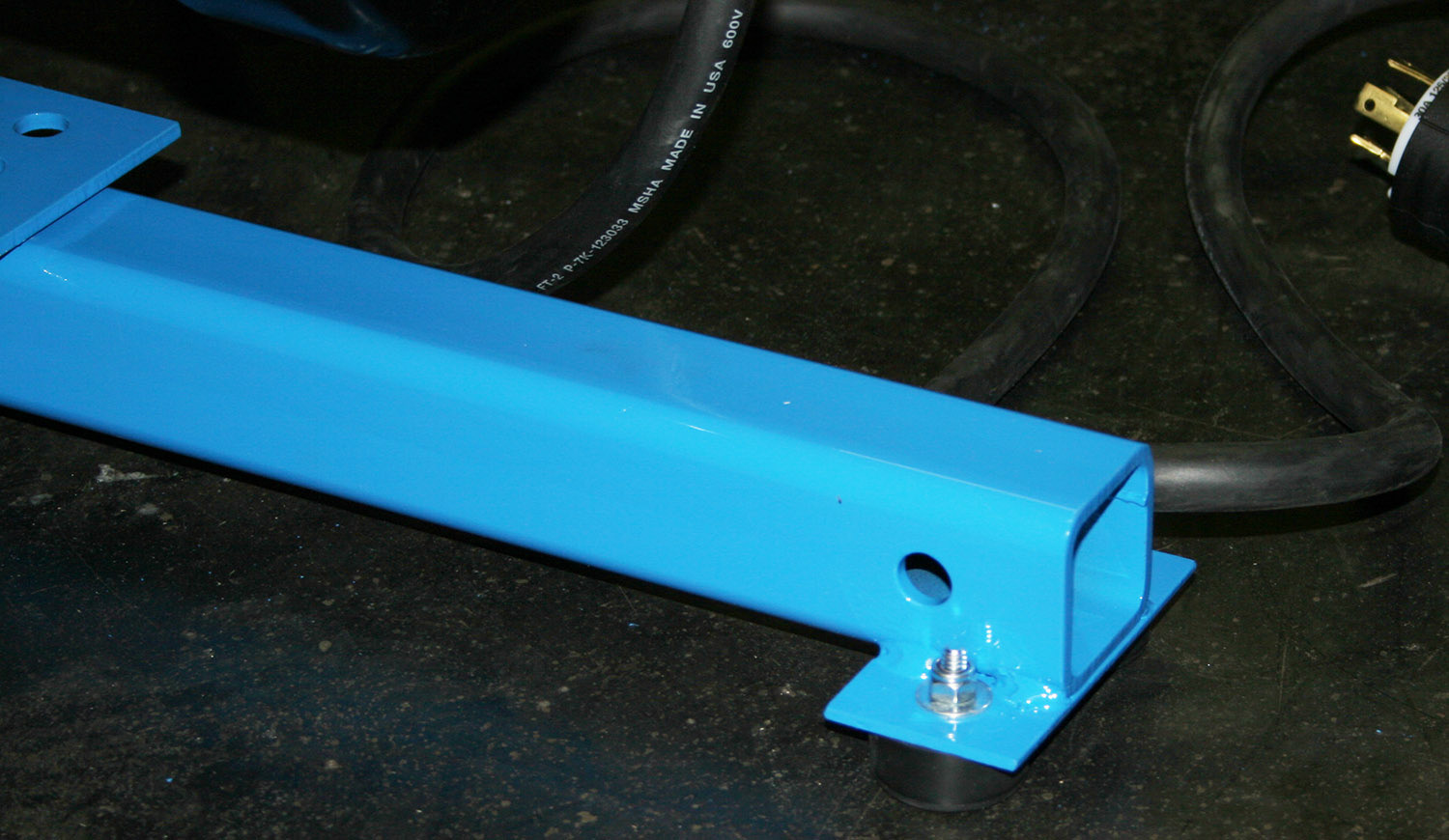

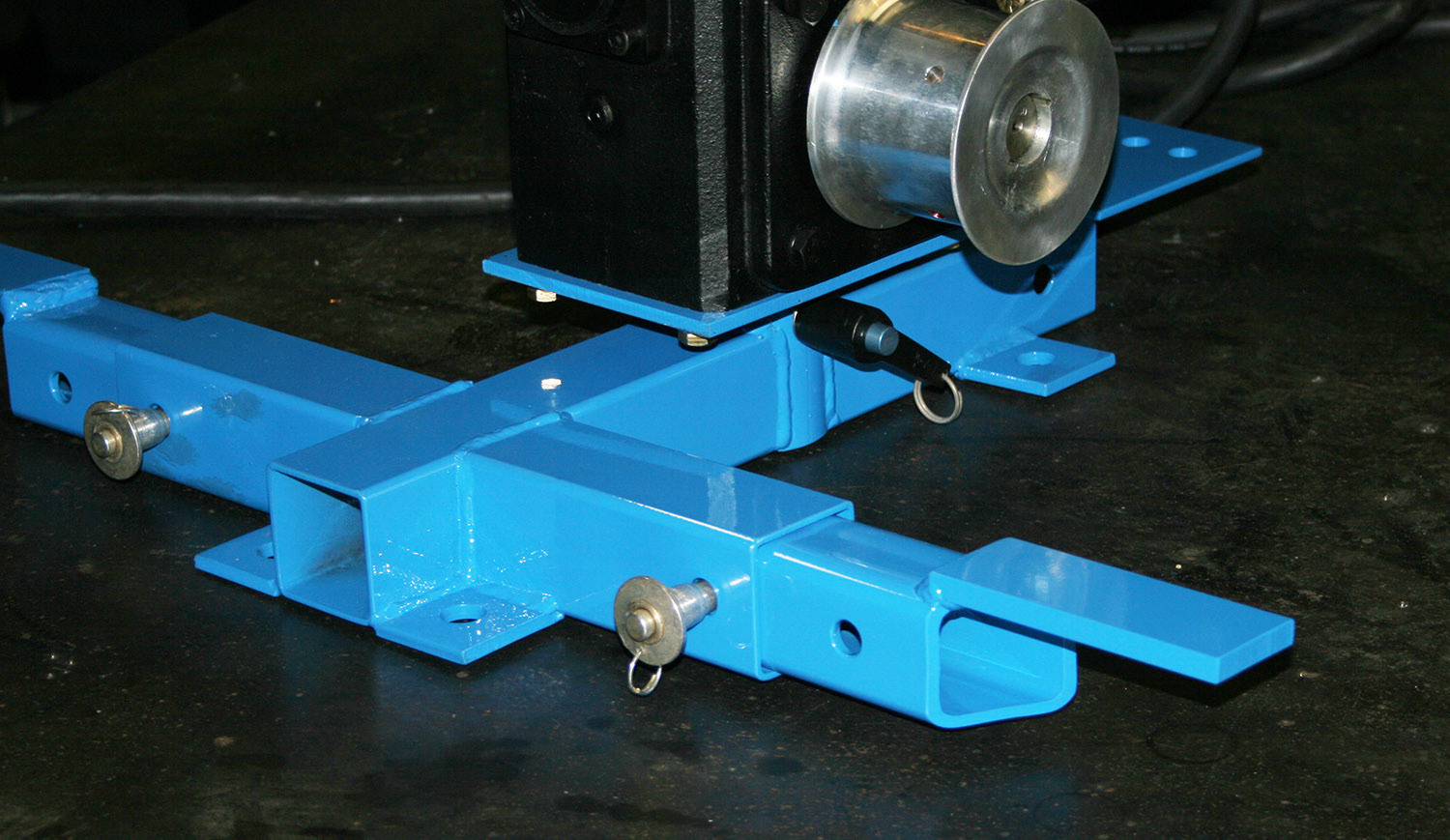

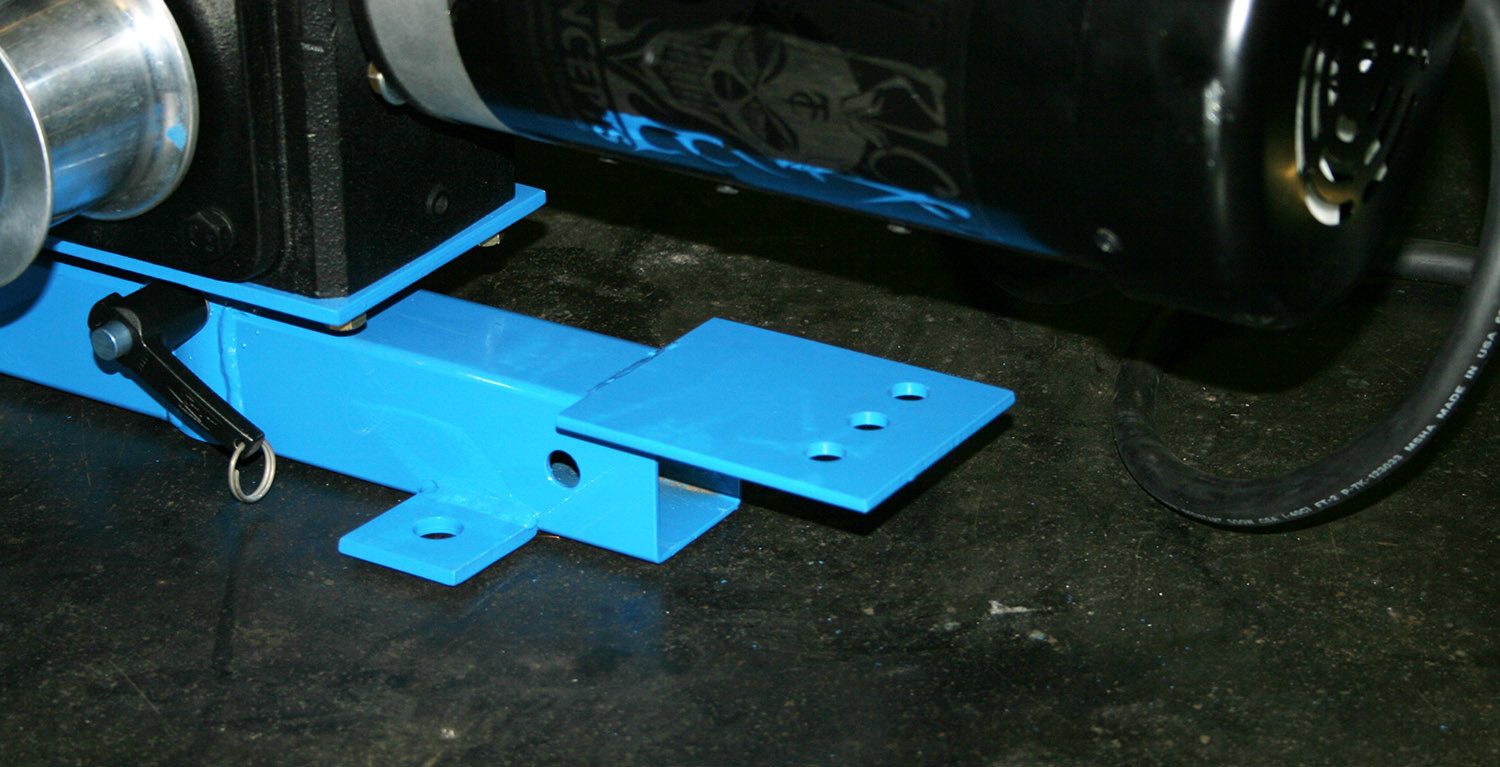

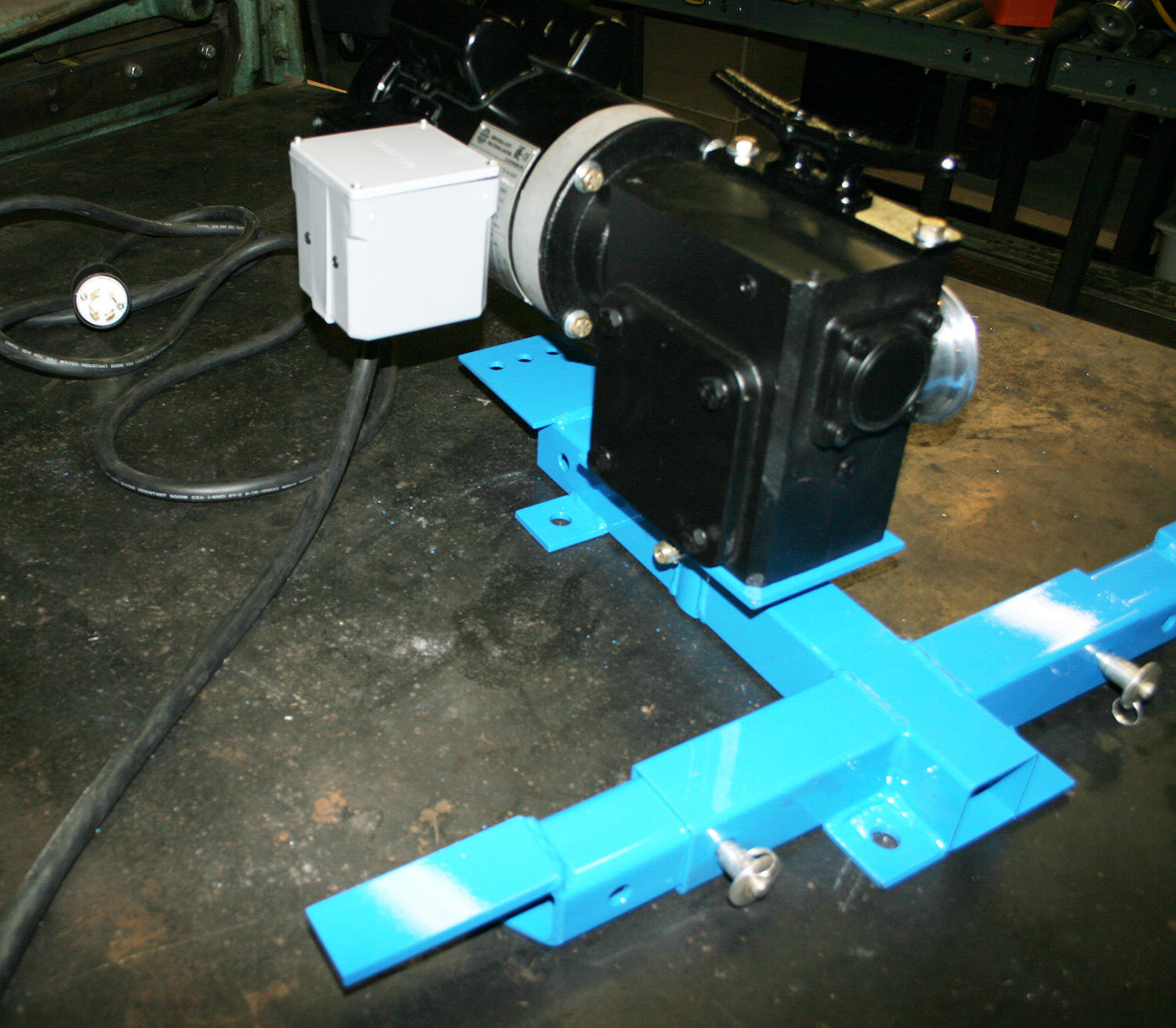

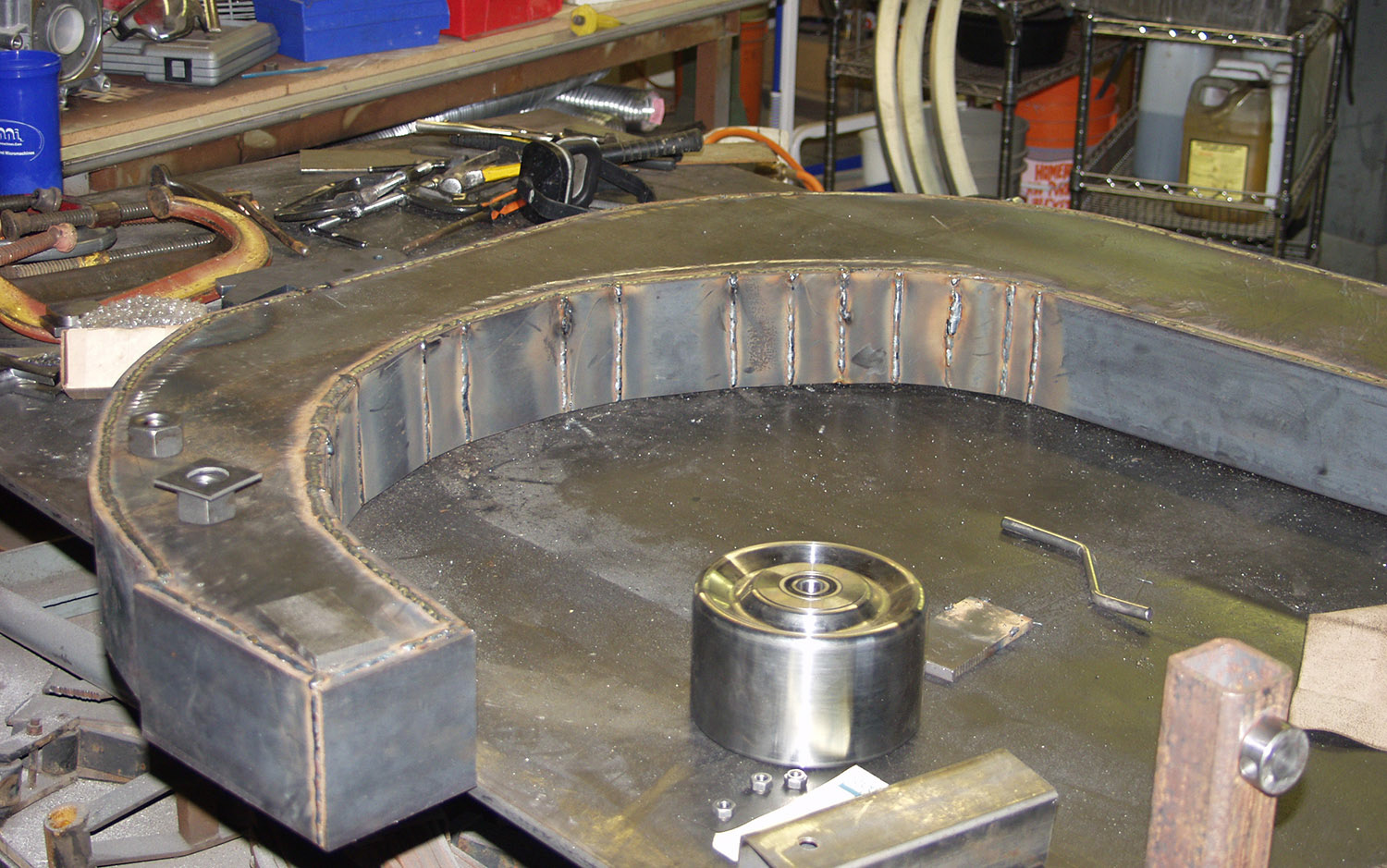

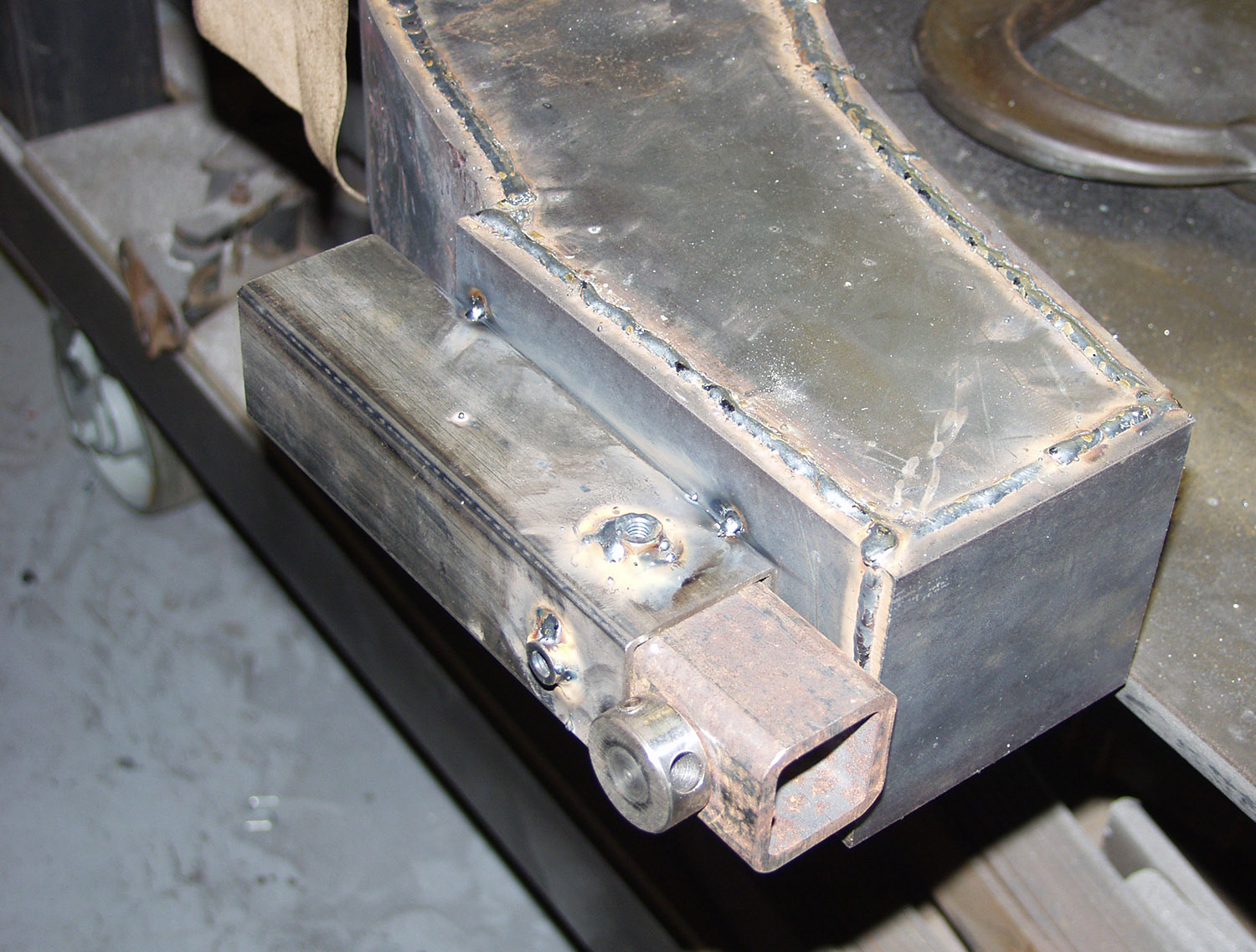

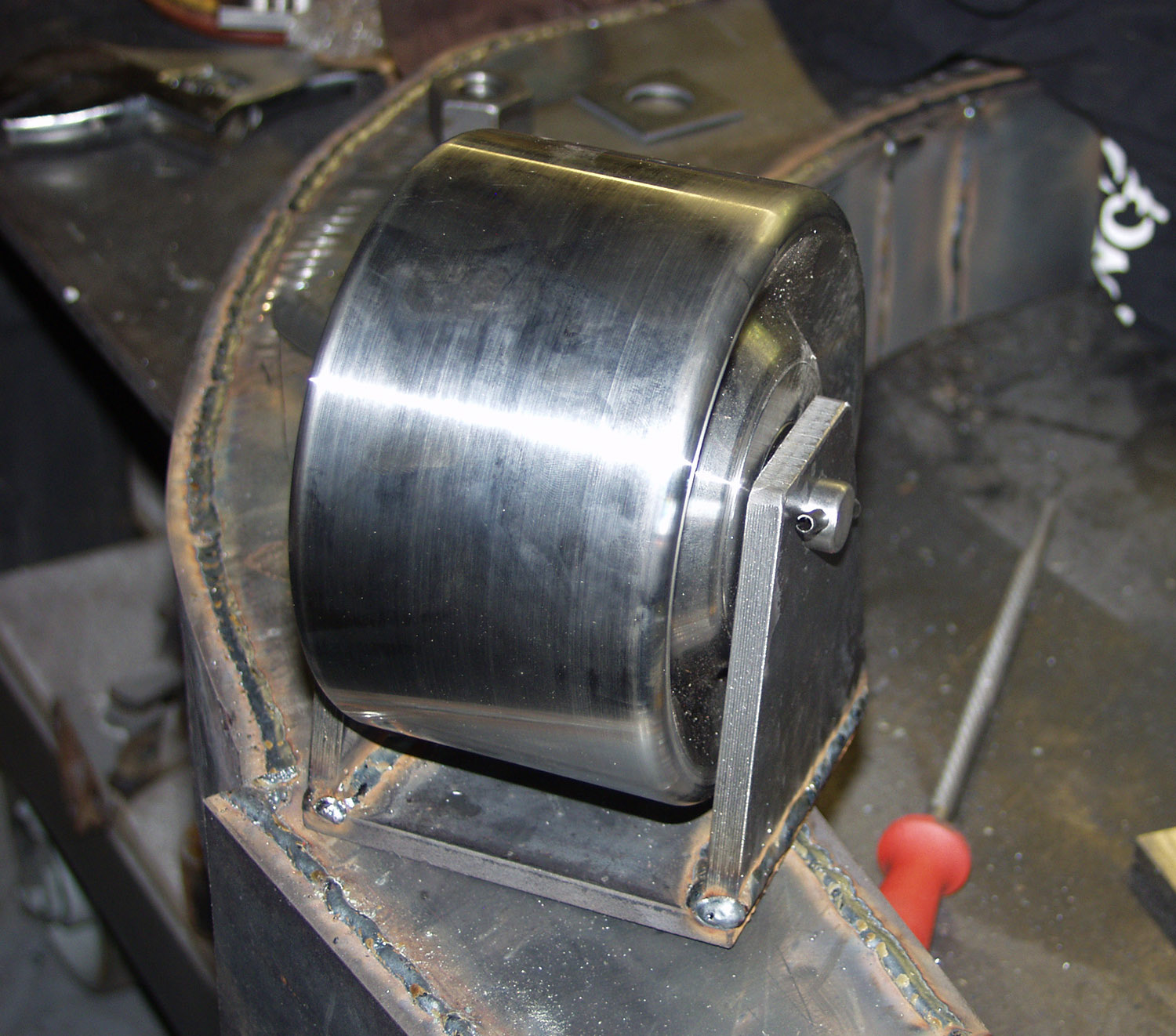

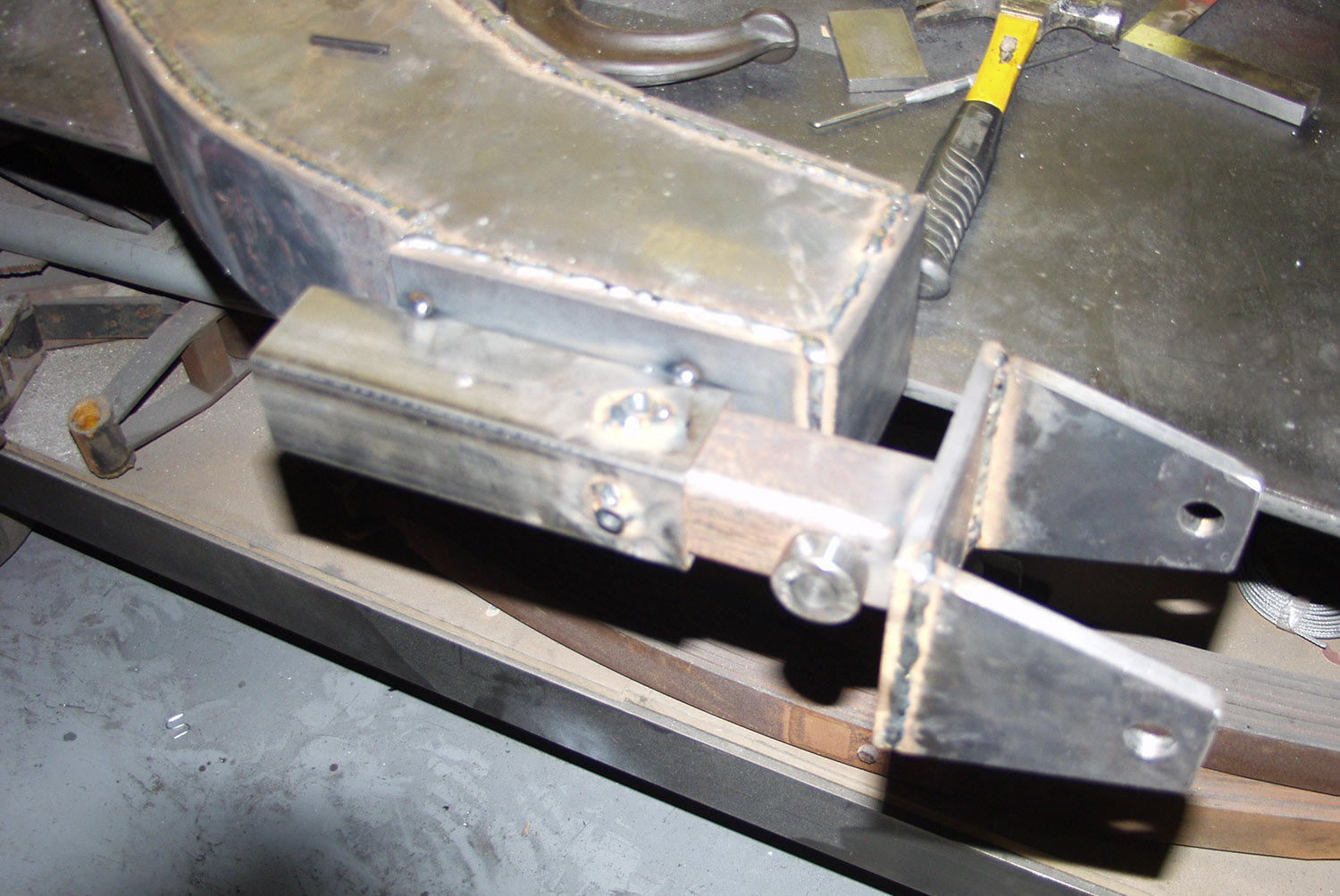

This is a project that I did for company that pulled fiber-optic and control wires through sewer systems. They needed a capstan that they could use to pull wires. I created three different designs for them. One design drops onto a manhole cover, another mounts into the hitch of a truck, and the third one just sits on the ground and is tied to a rigid object. I made 4 of these units for them.

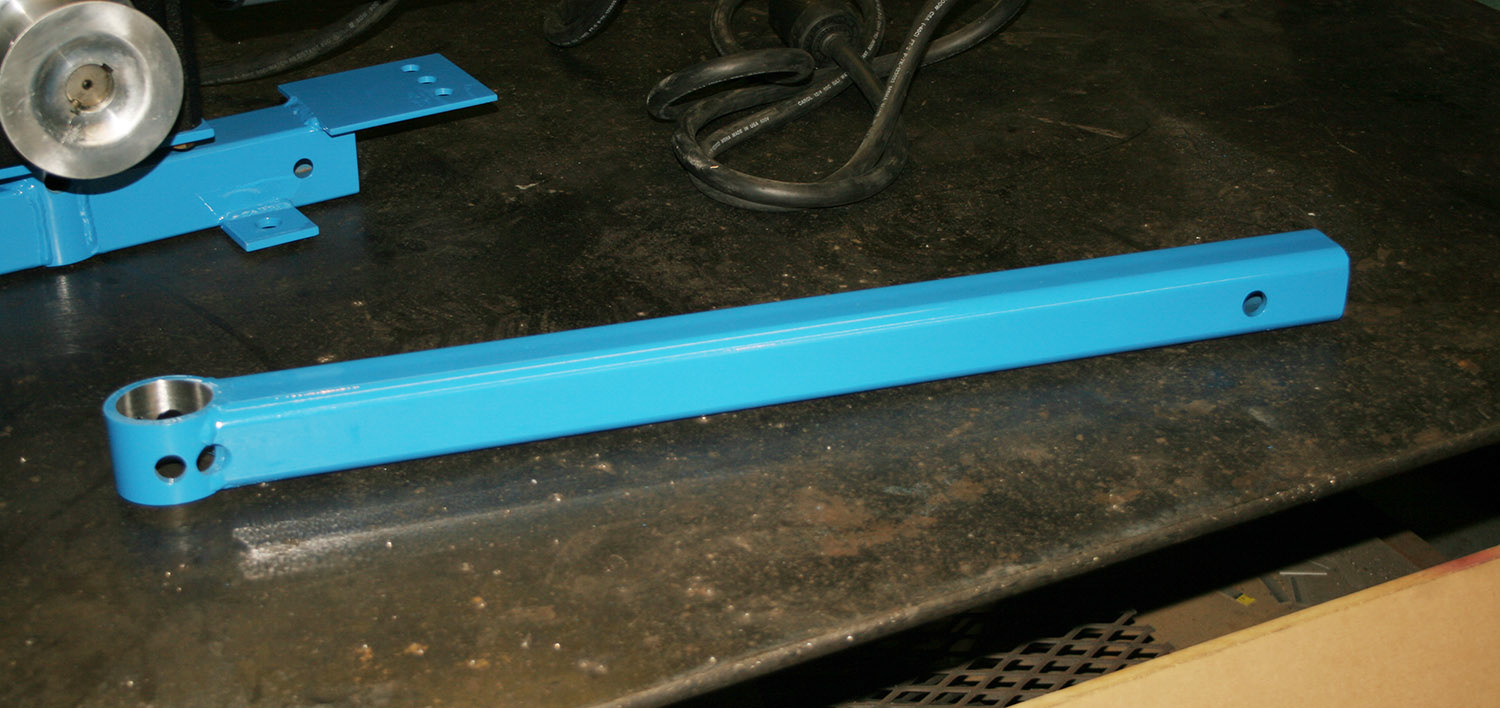

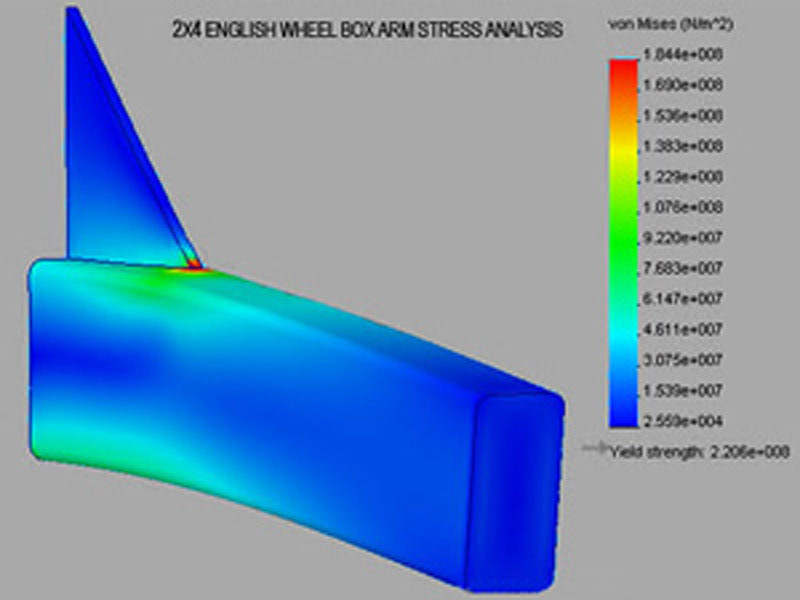

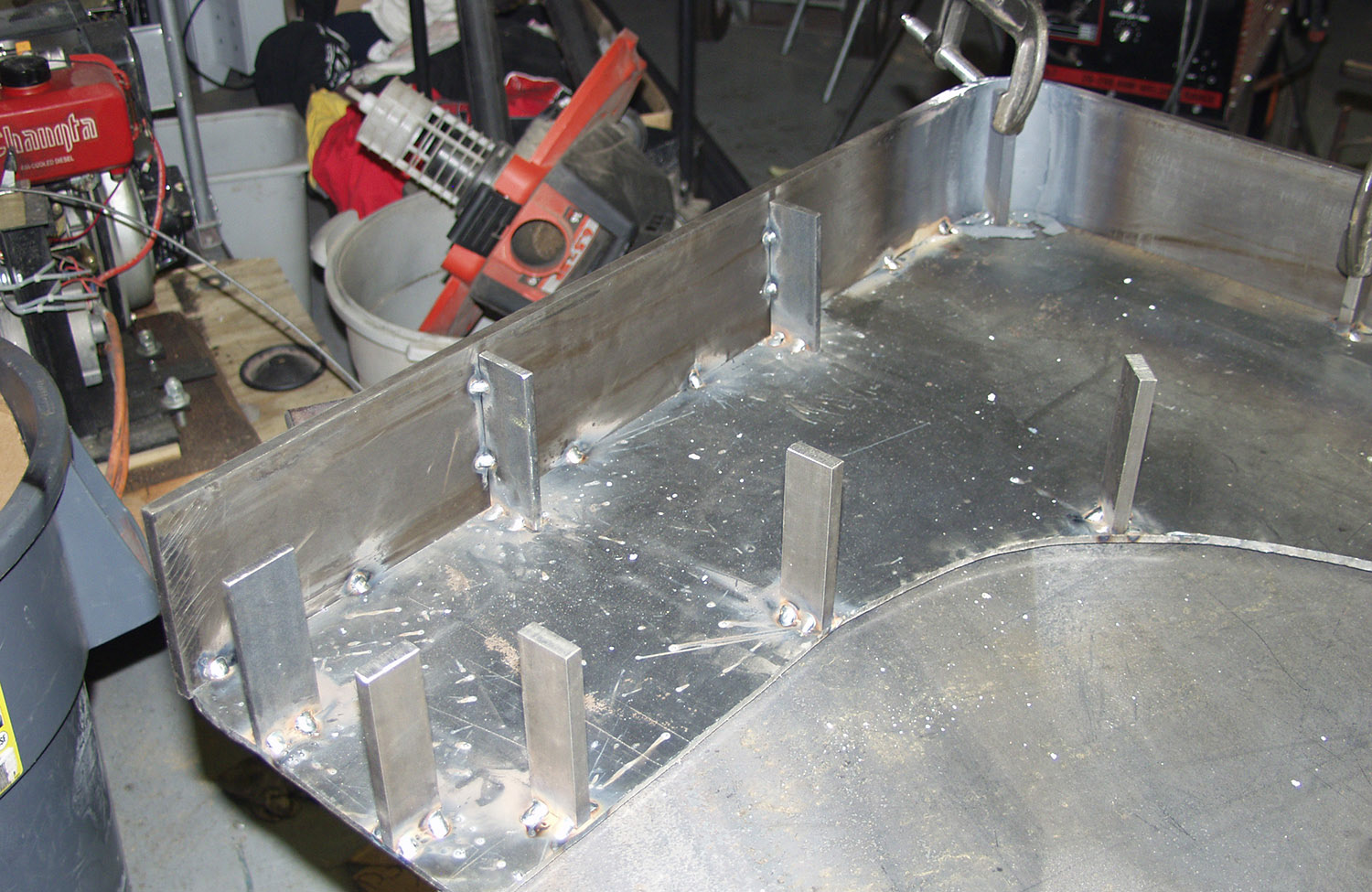

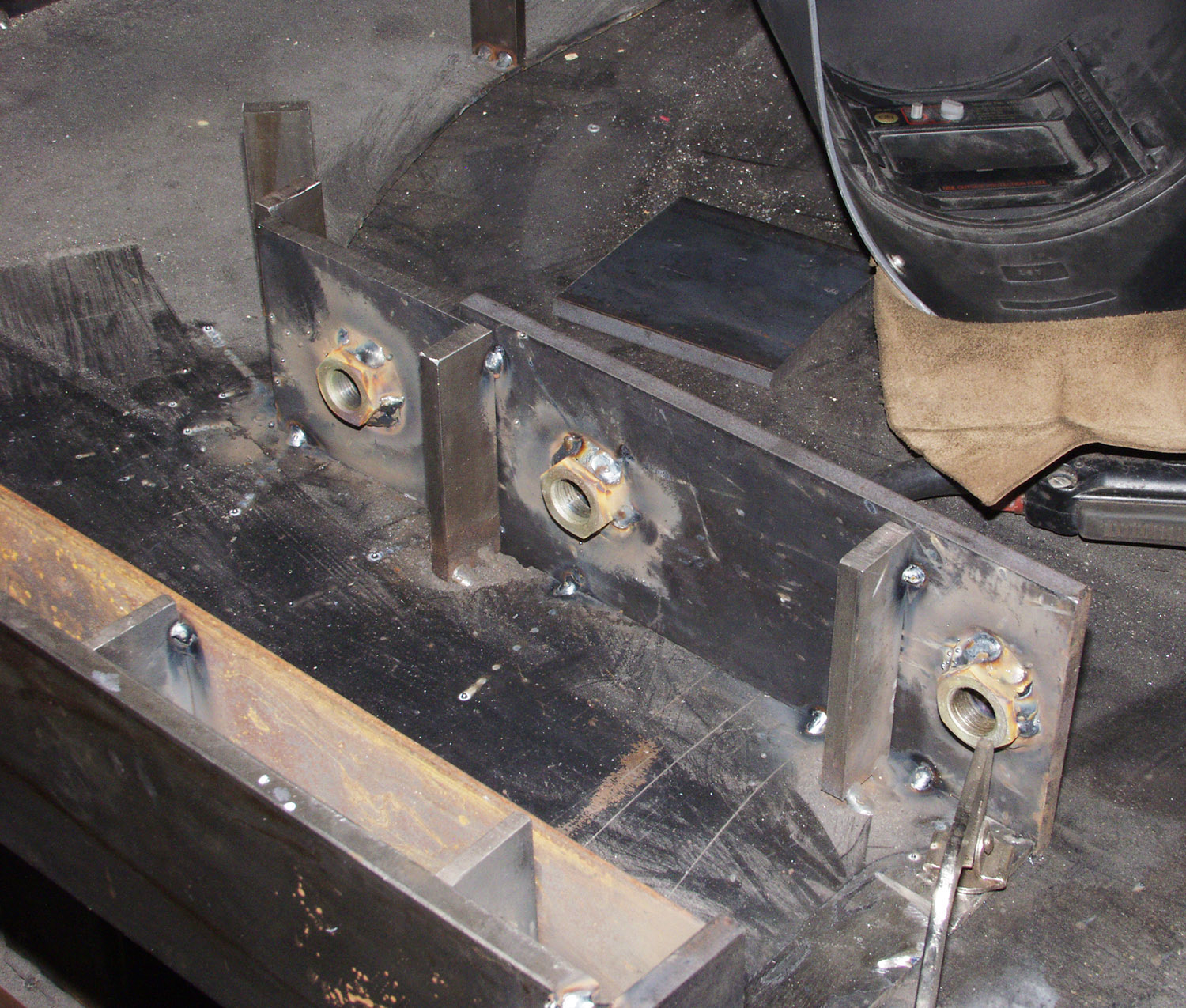

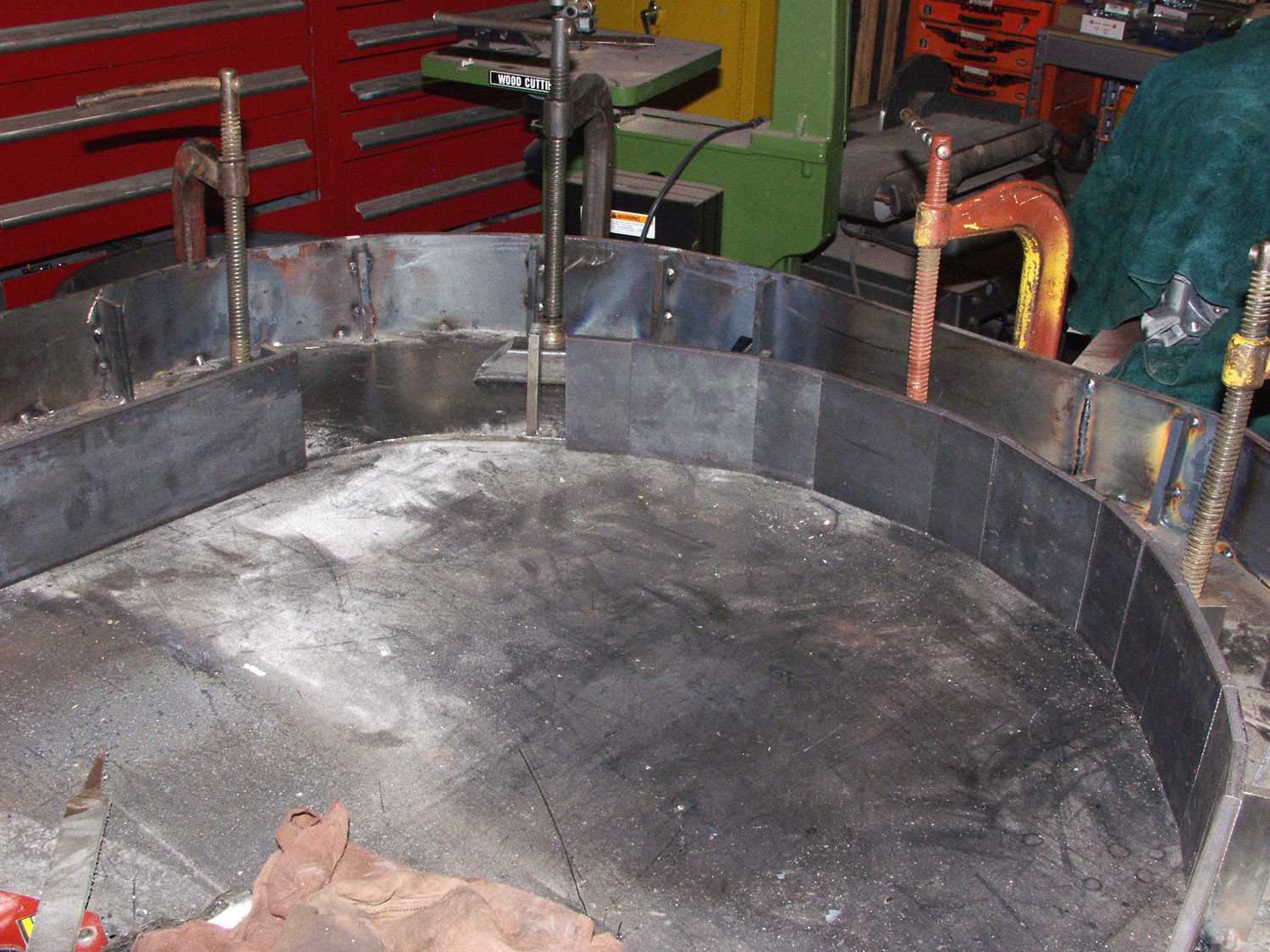

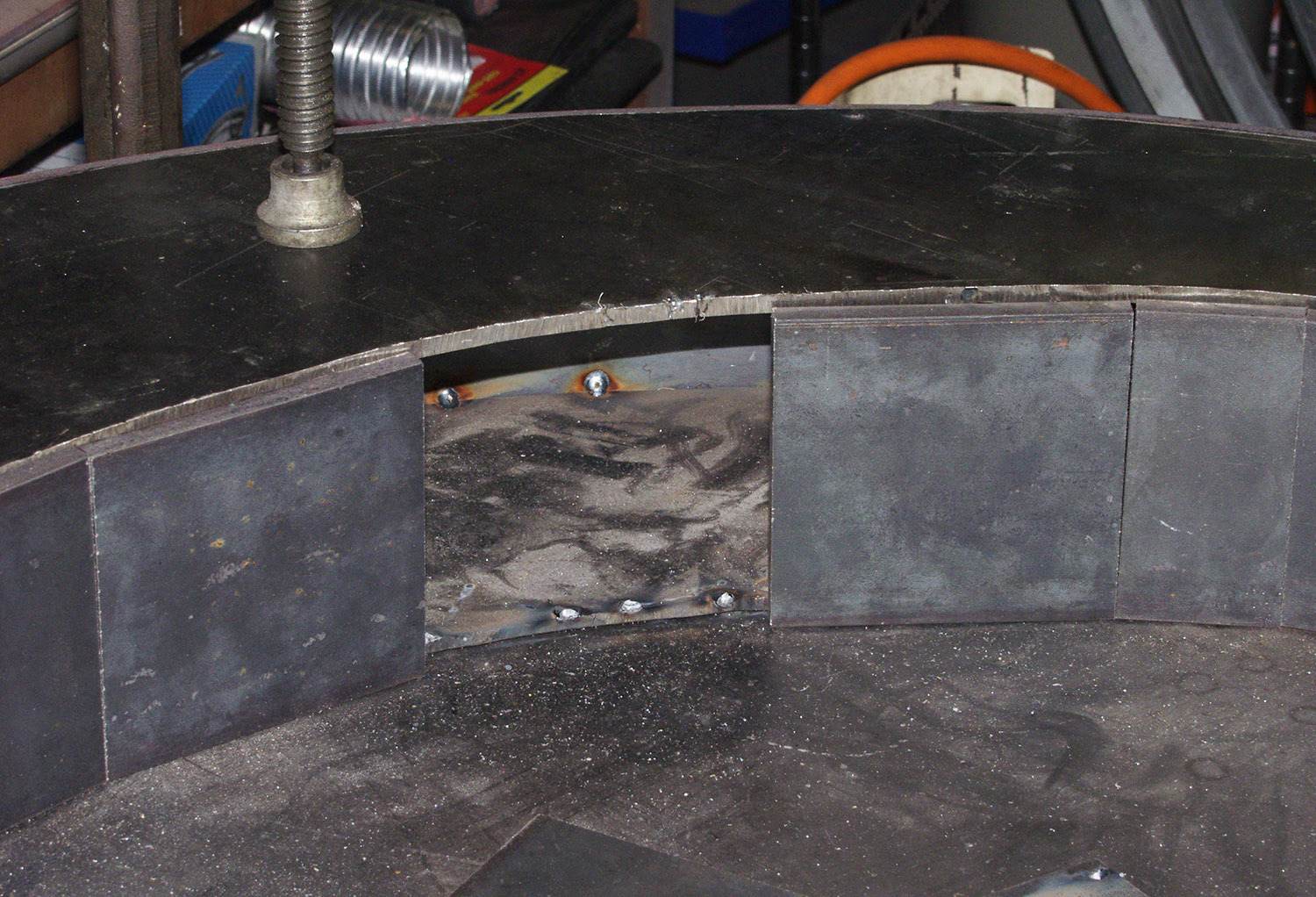

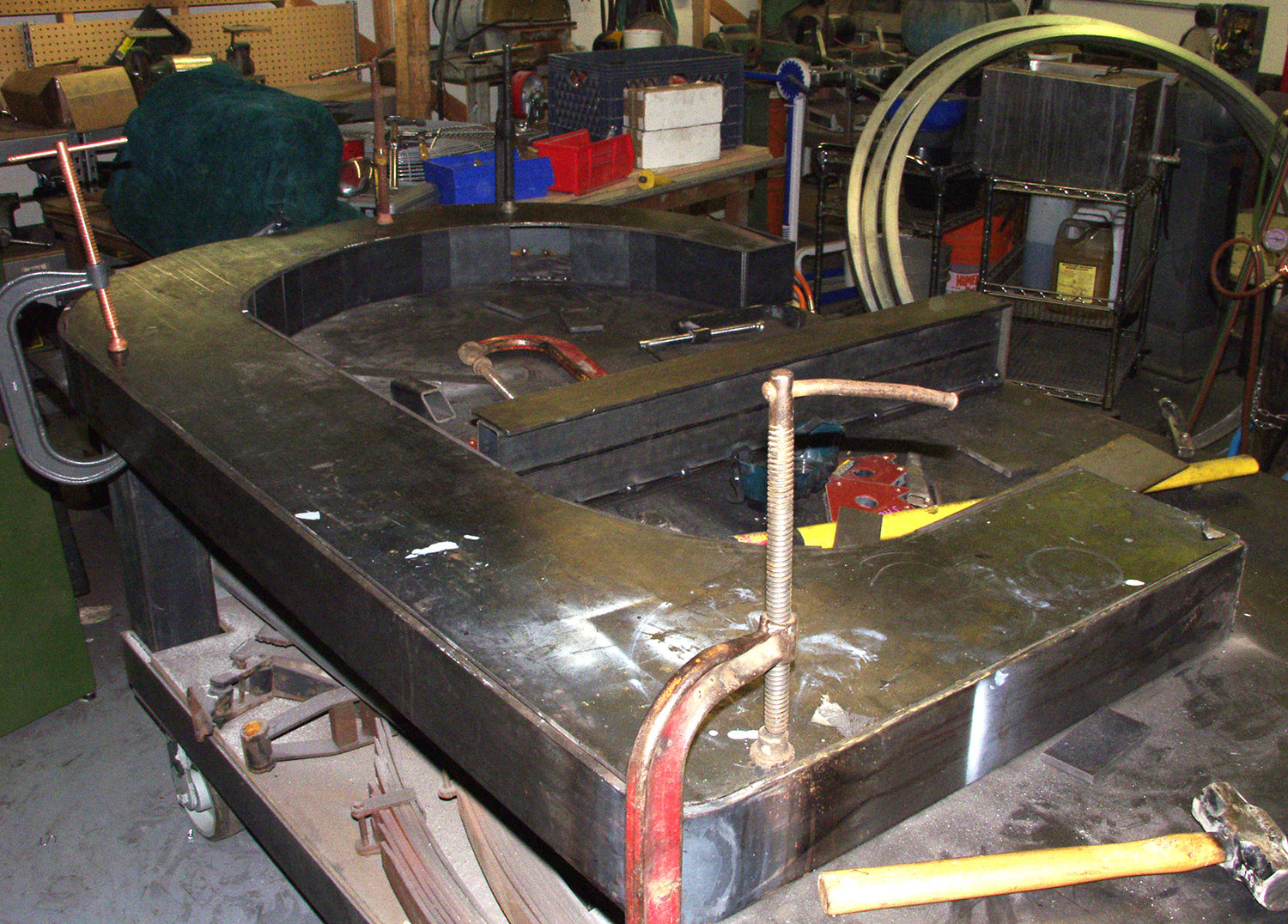

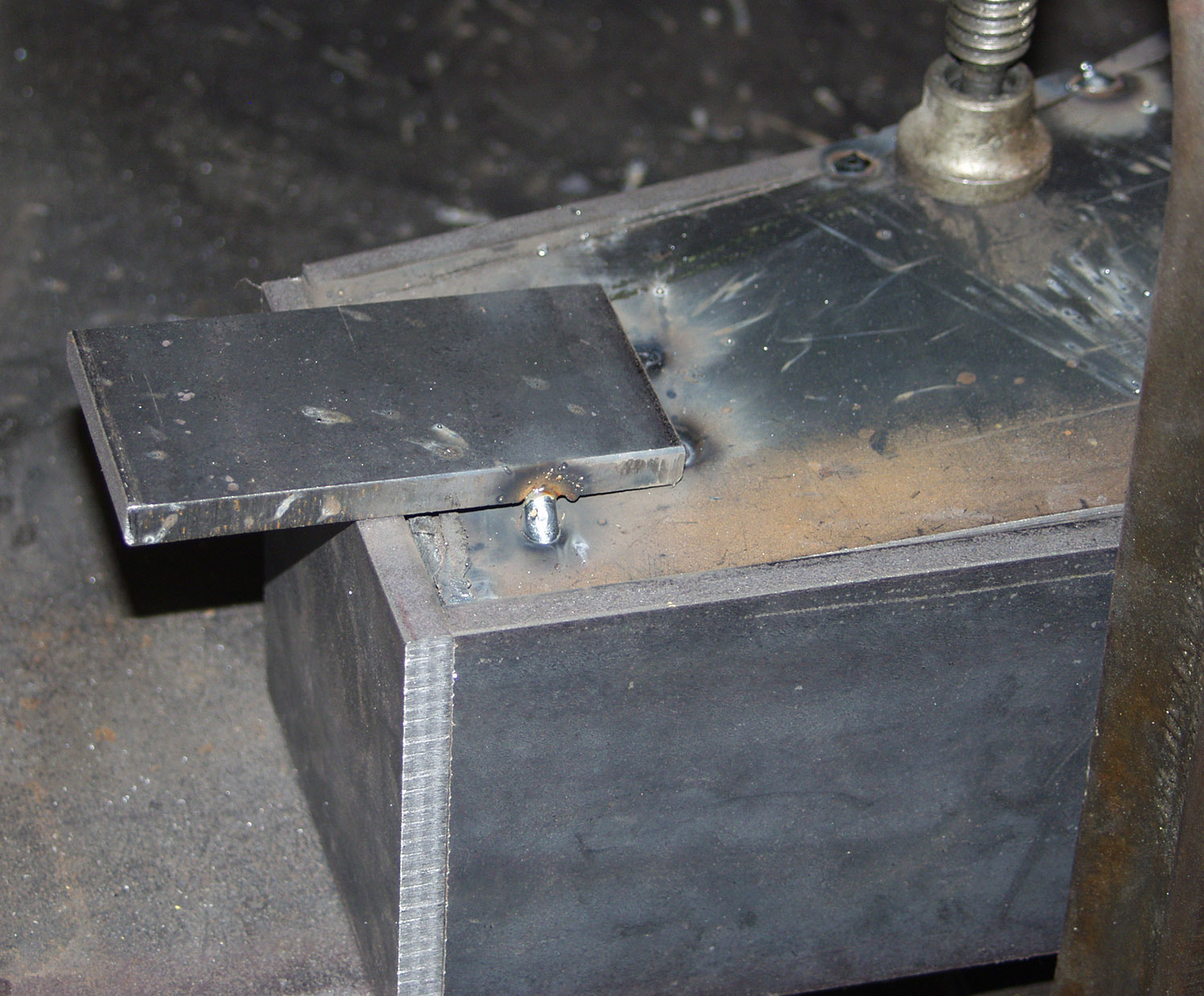

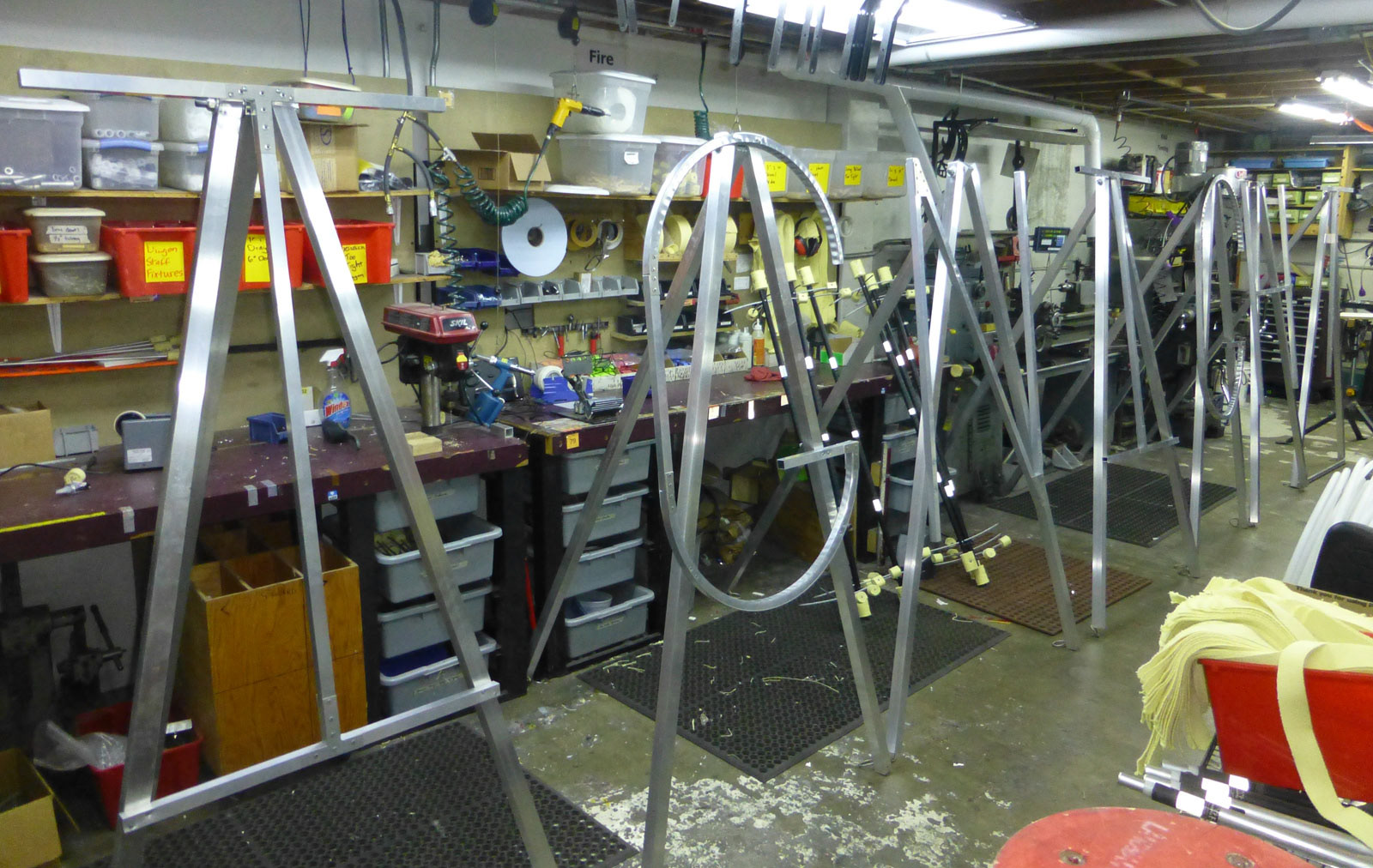

For a short time, I had a business where I manufactured English wheel kits. You could buy a frame kit and weld it together, or you could just buy the machined wheels and build it yourself from scratch.

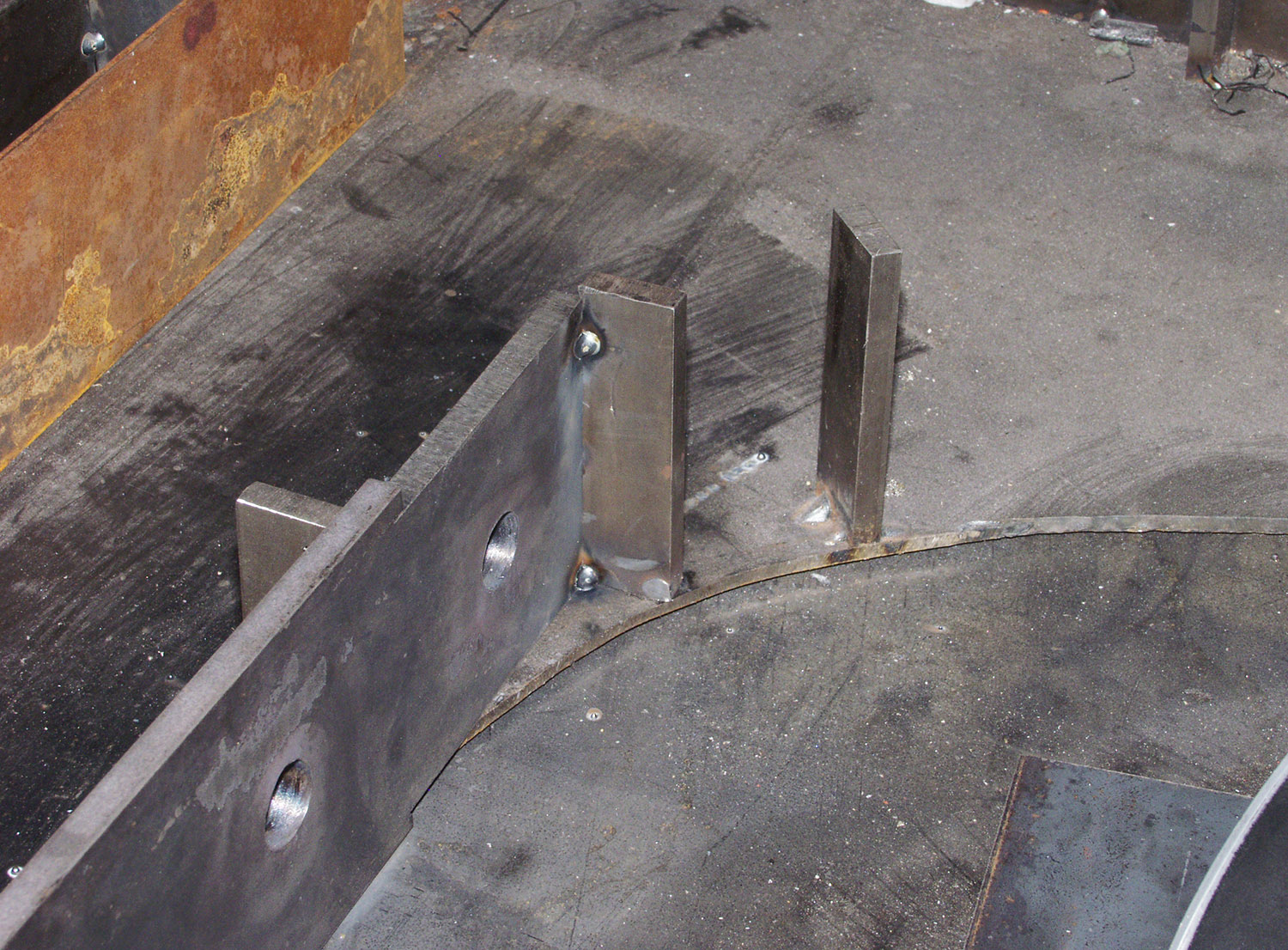

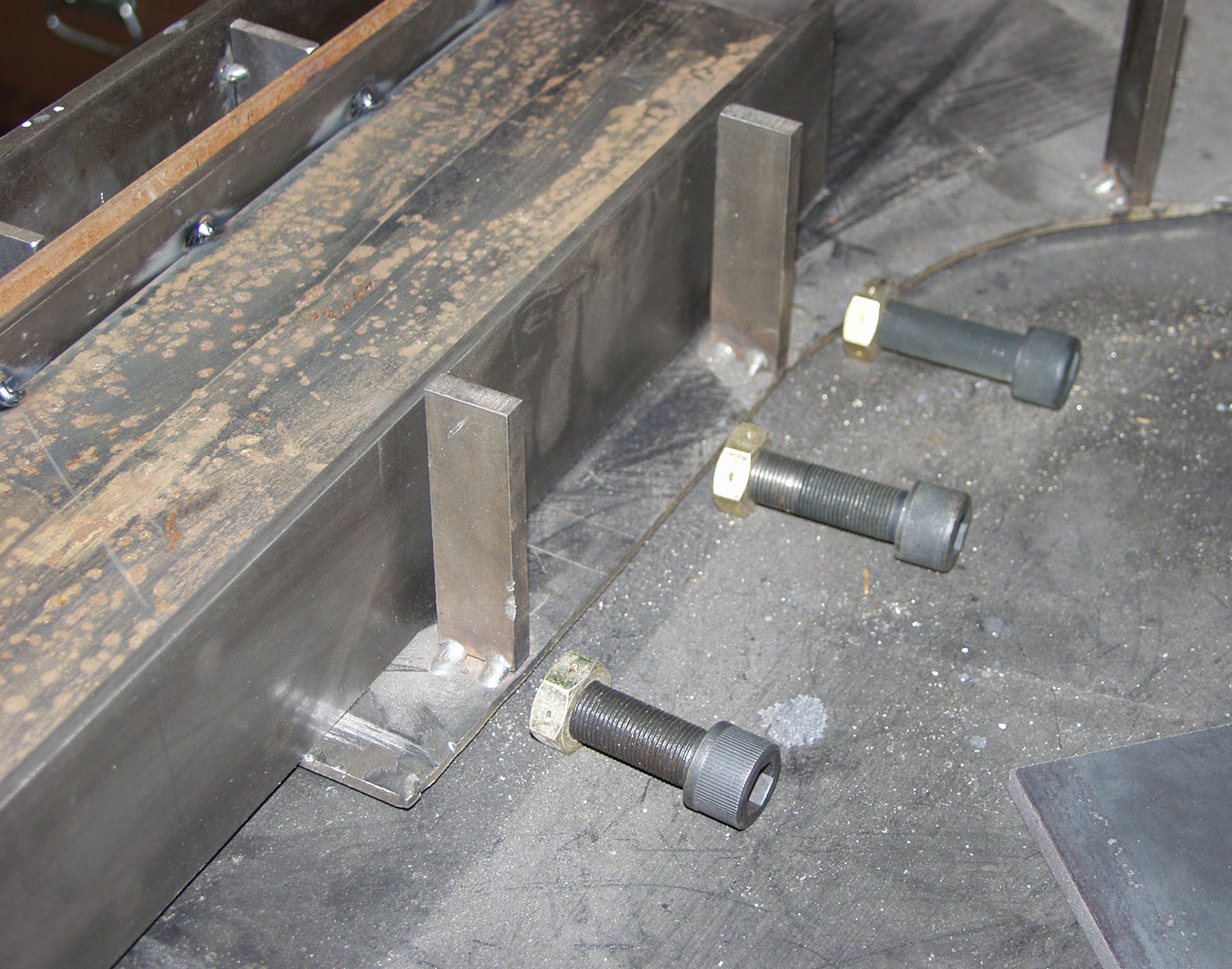

This is an English Wheel build I did many years ago for myself. This was before I had built my CNC plasma table so everything was done by hand. I added a lot of adjustments to the design of the top and bottom wheel mounts that would allow parts be formed that could not be done on a traditional machine.

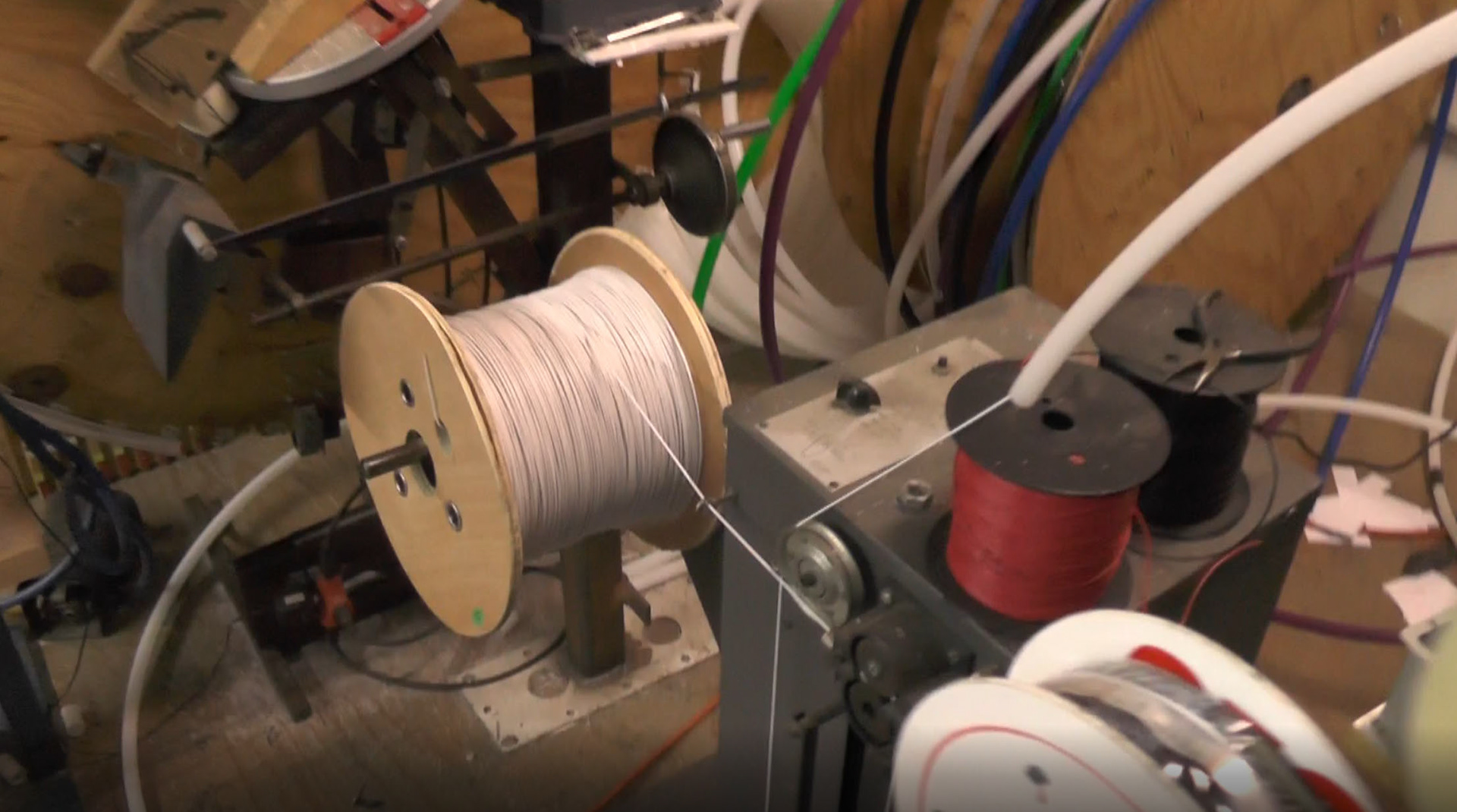

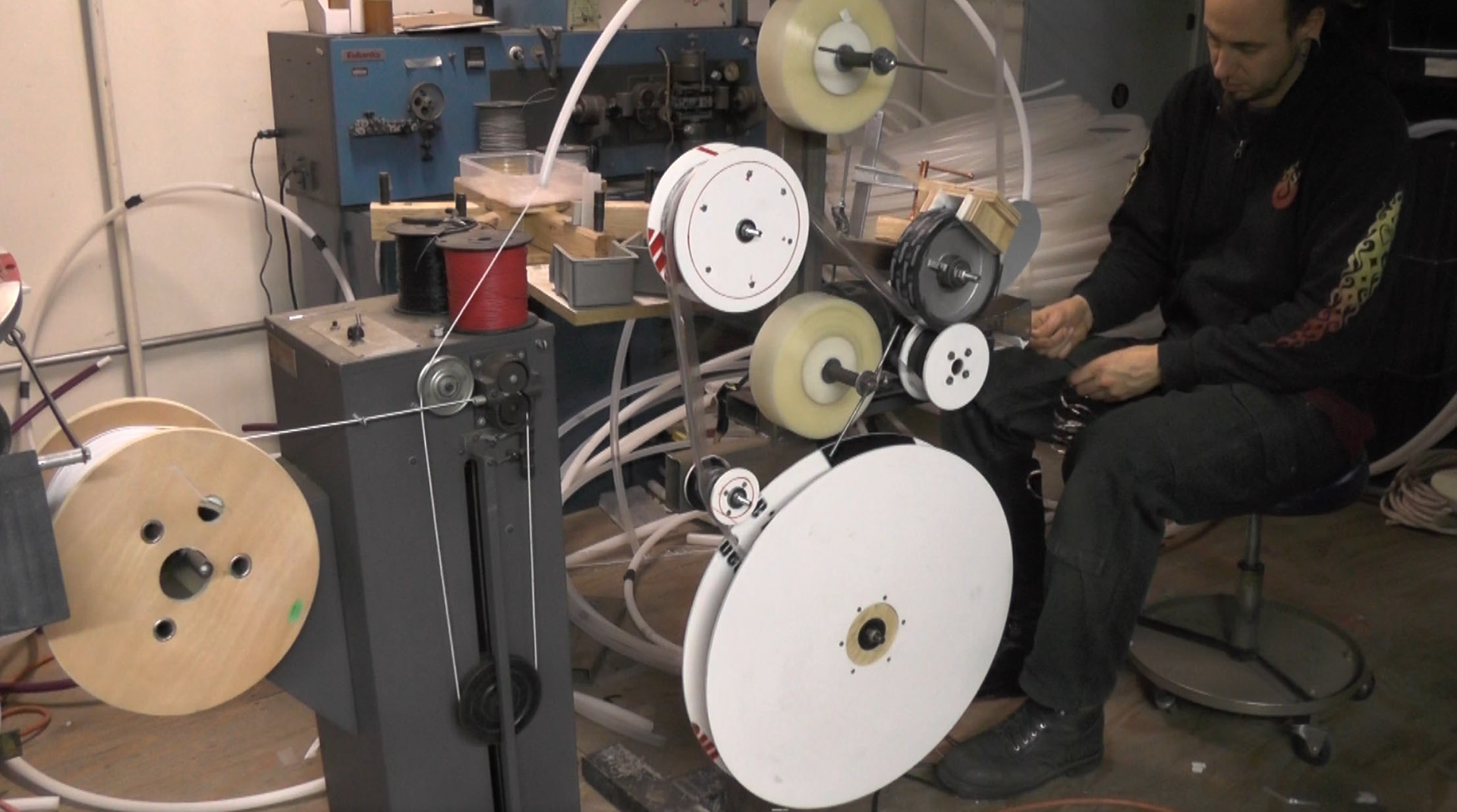

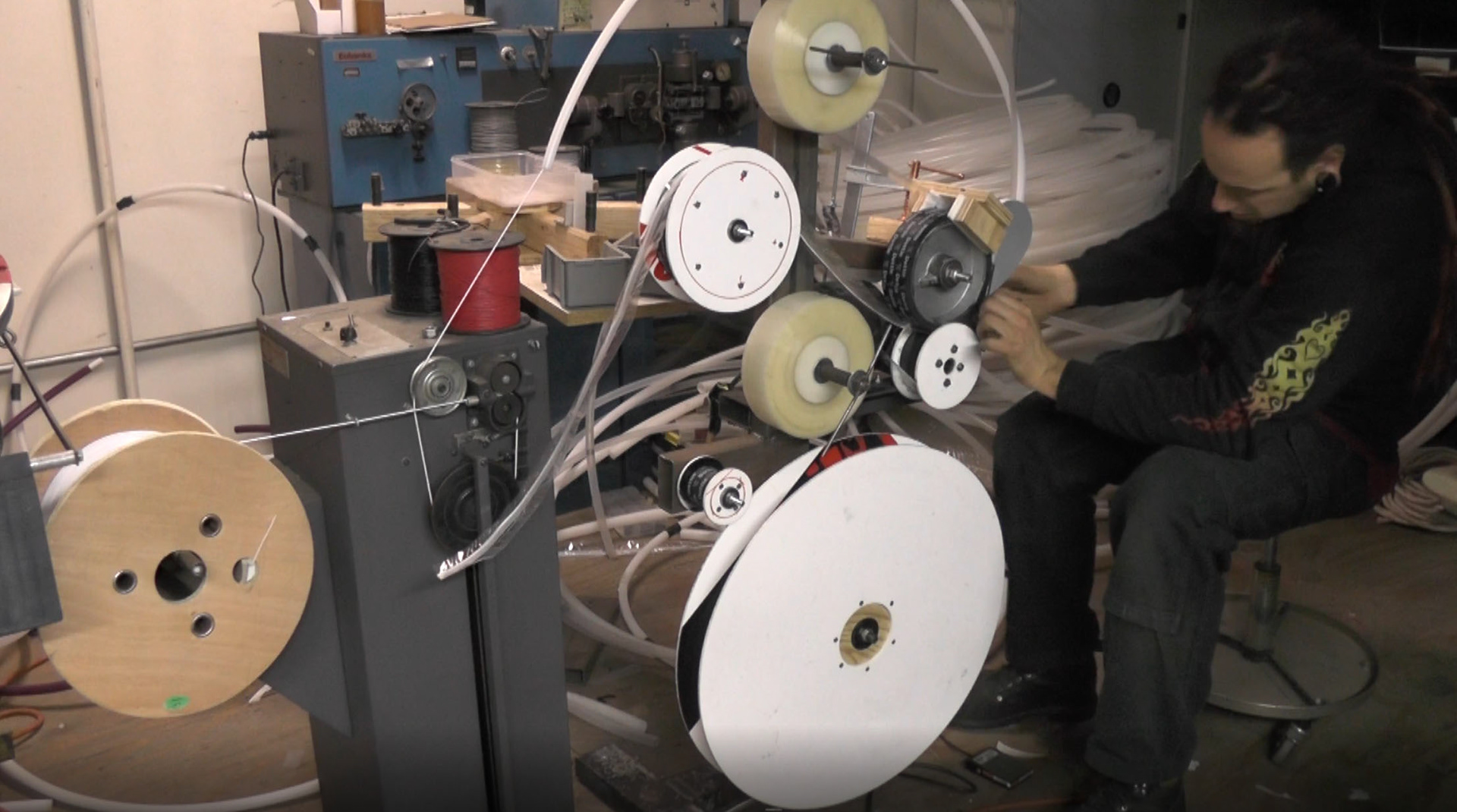

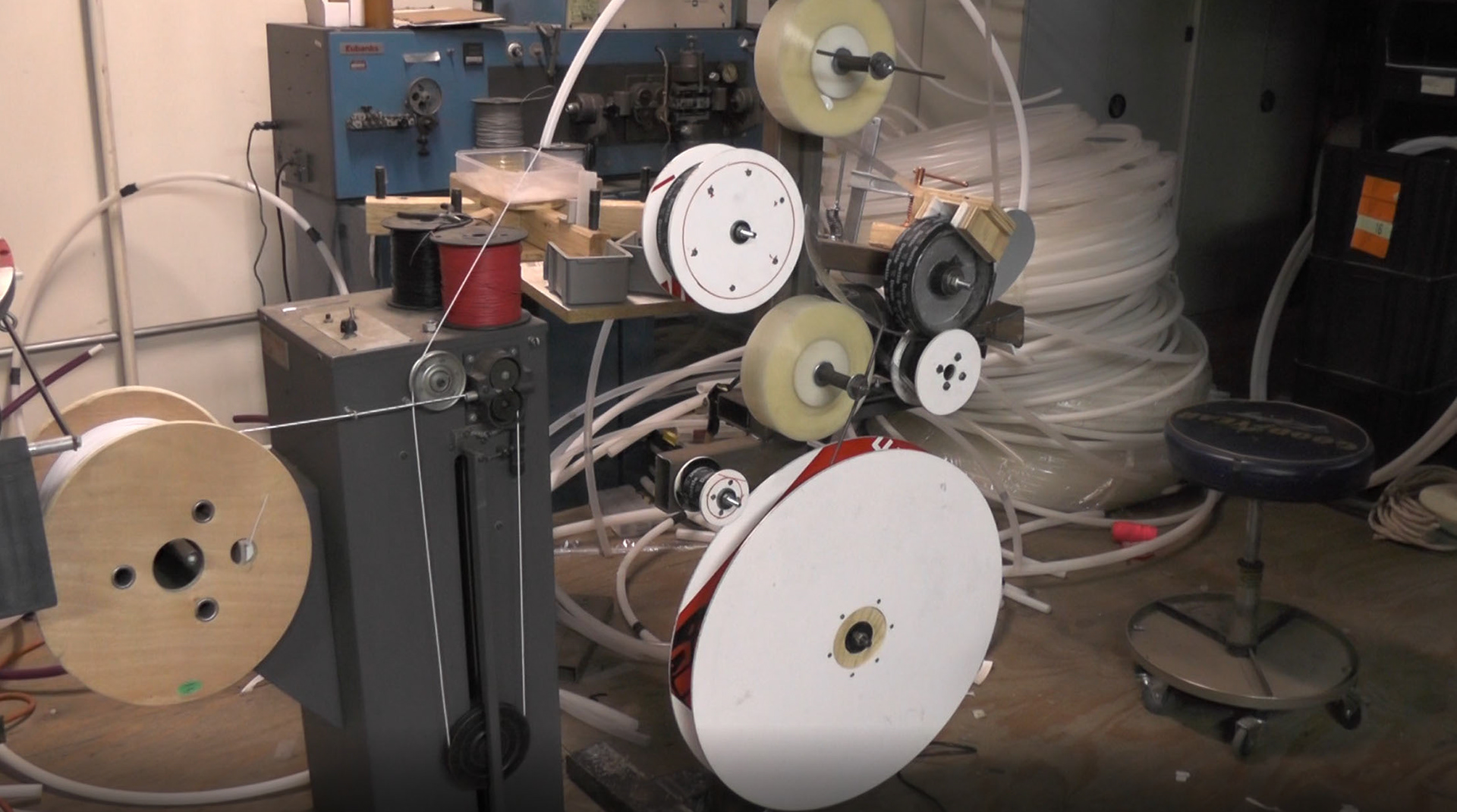

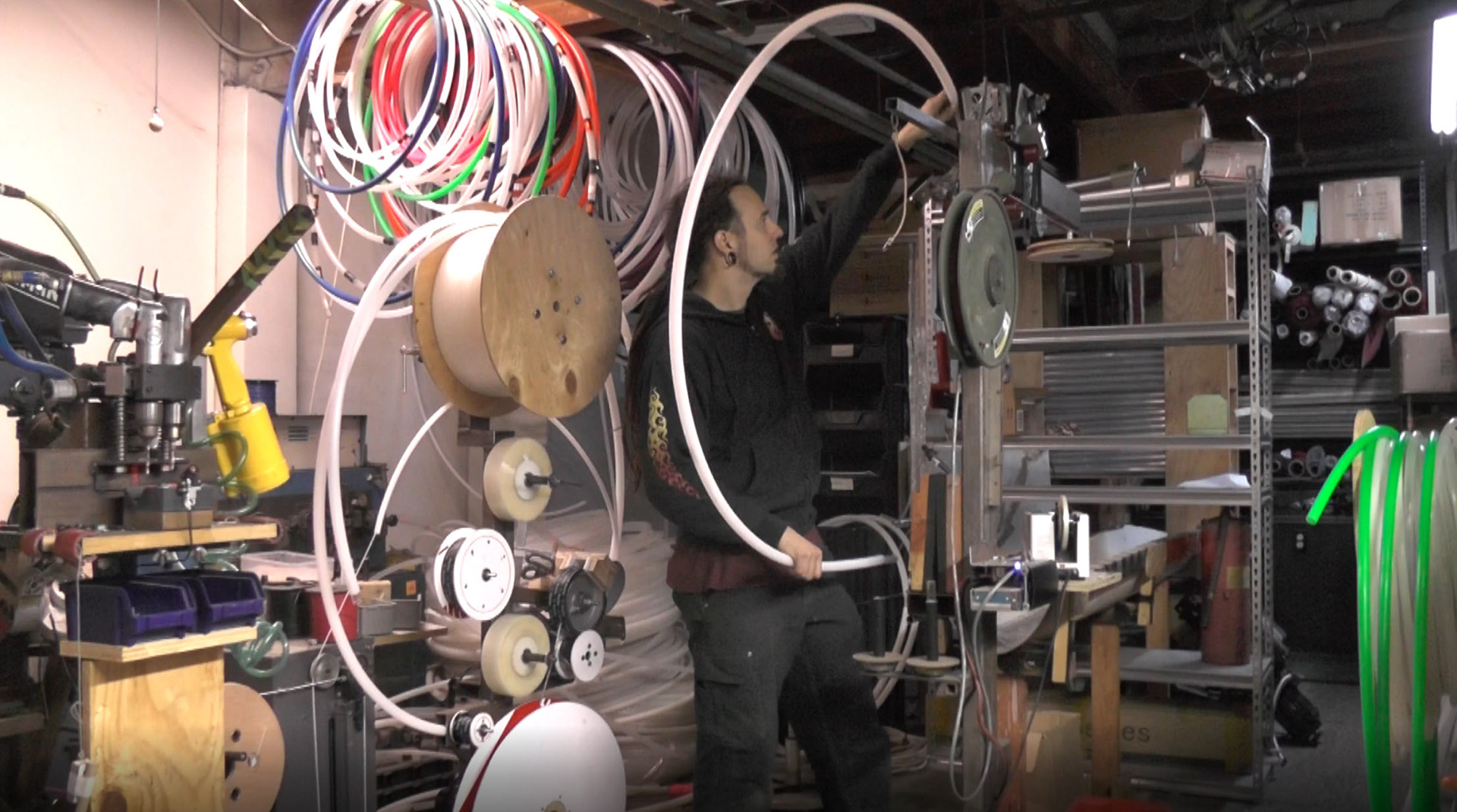

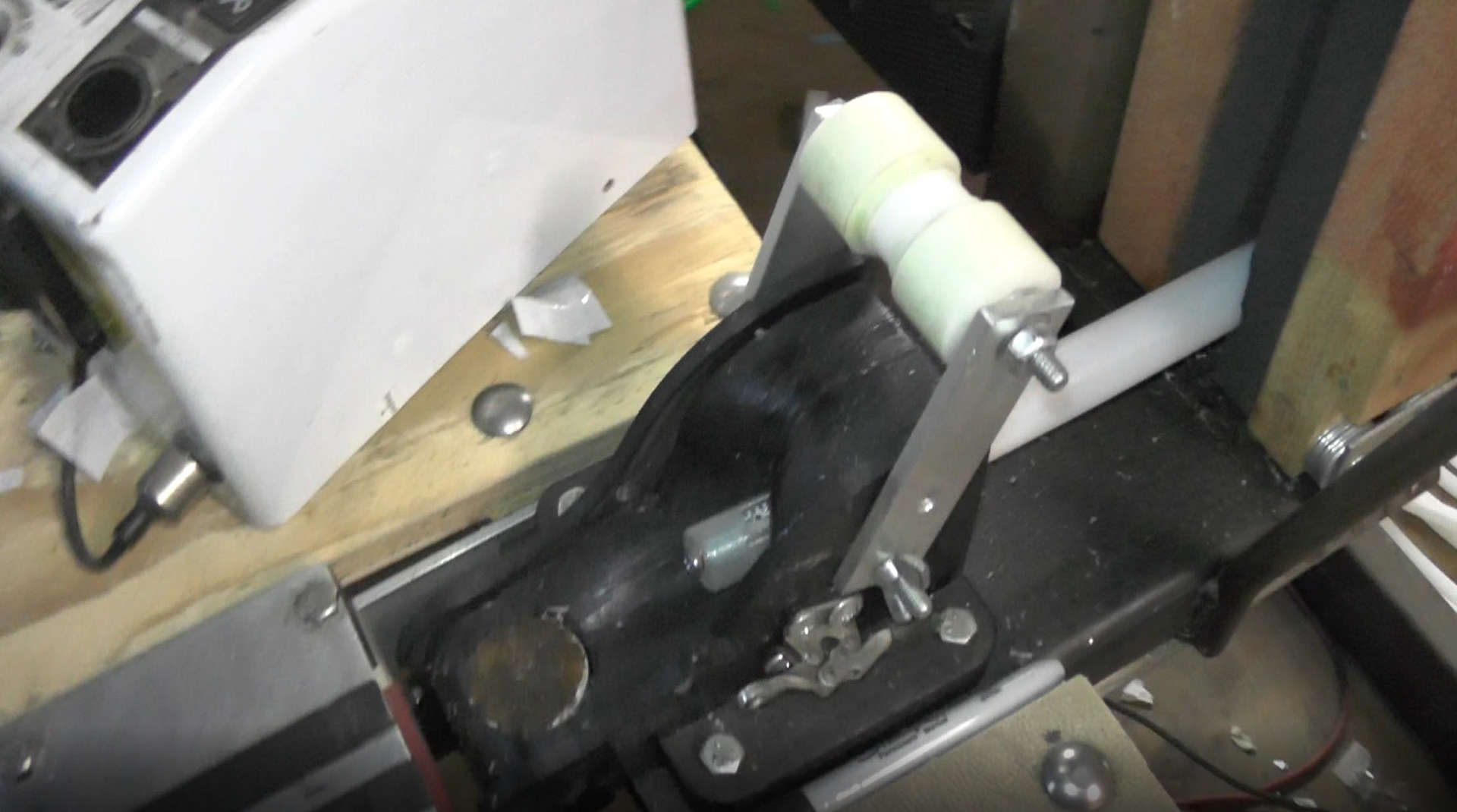

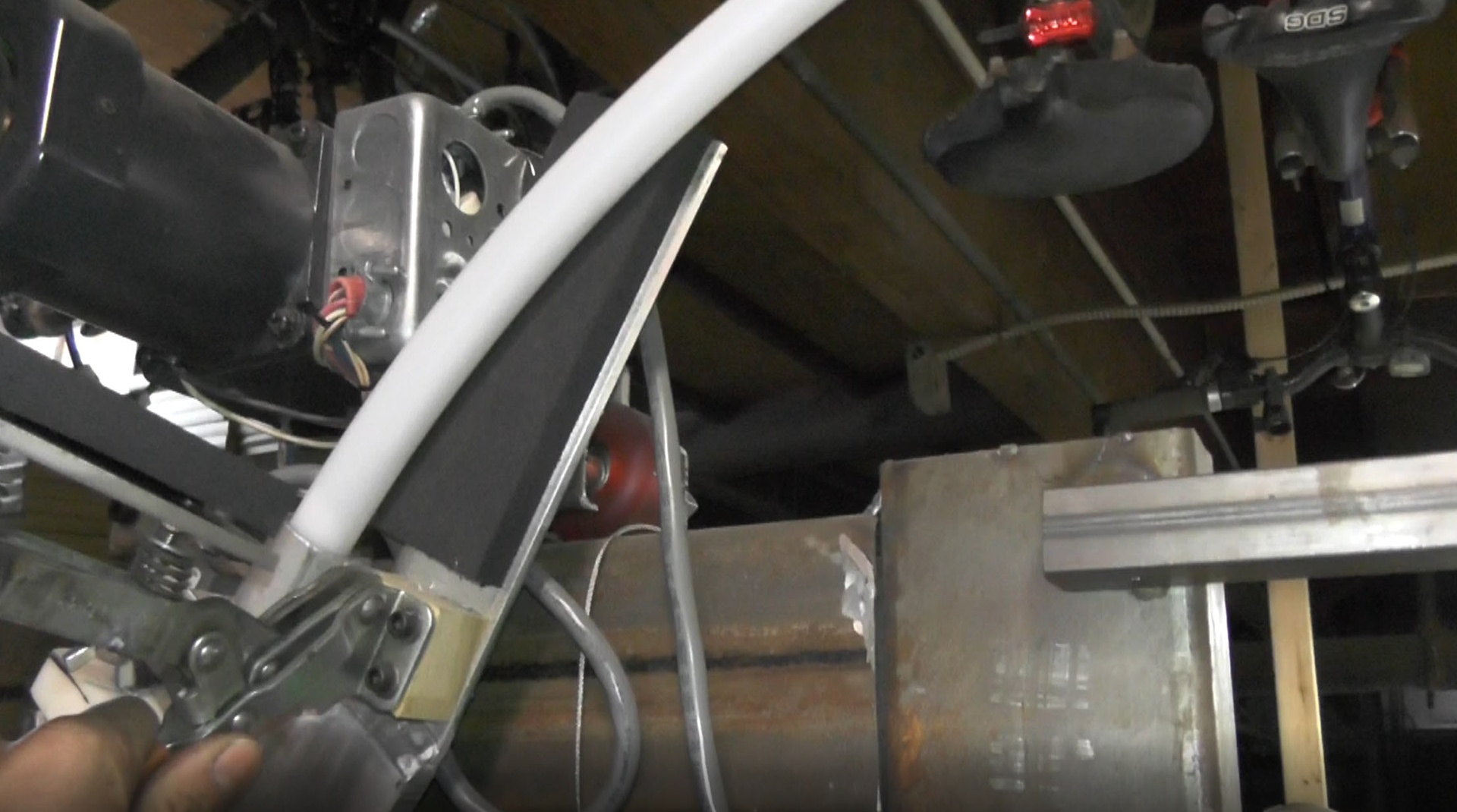

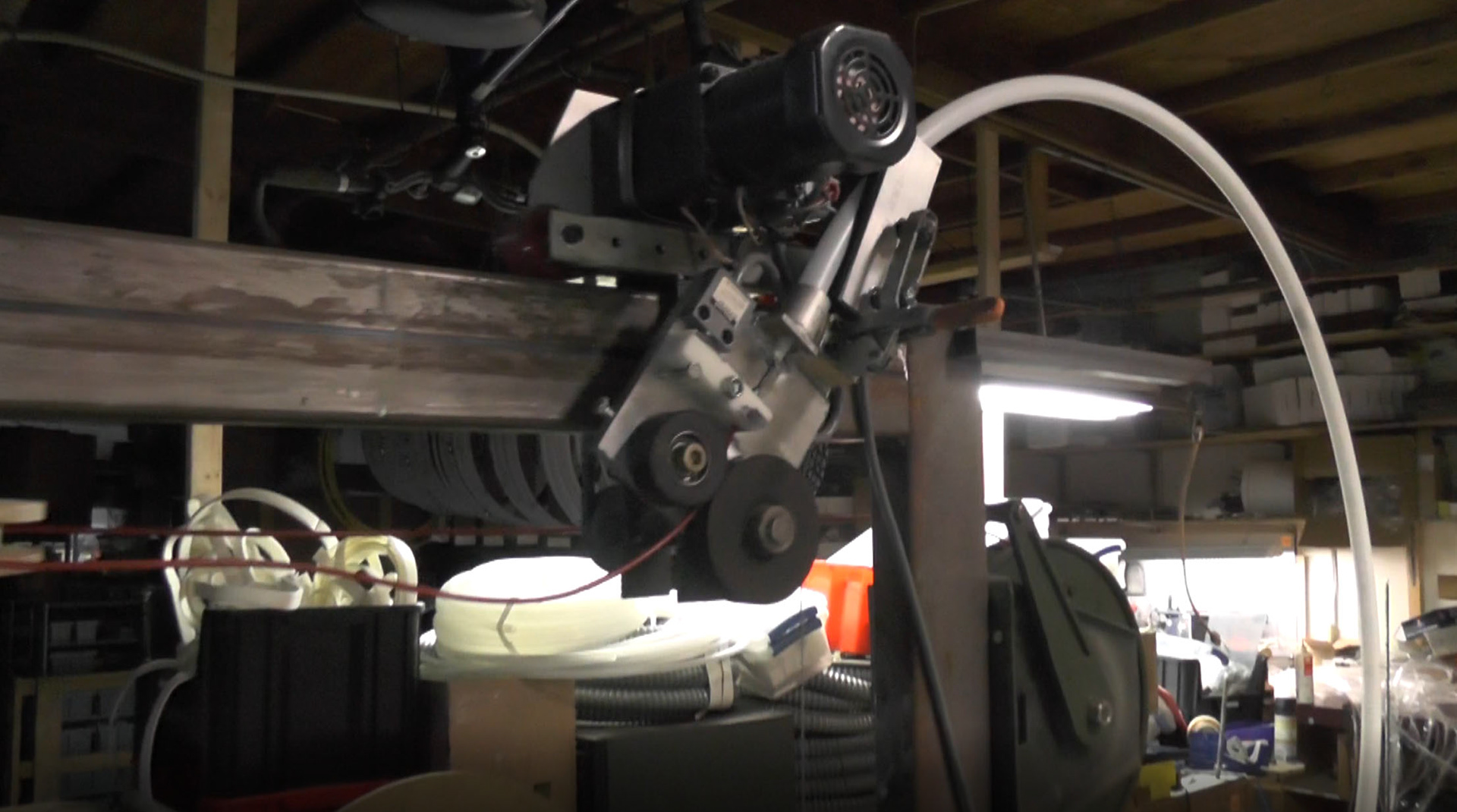

This is a machine that I designed to automate the process of making LED Hula hoops. It was just used in house so was purely design for functionality, not appearance. This machine reduces labor input by about 90%.

A sign I made a restaurant in Los Angeles a long time ago.

A signed a made for a fire Festival. The sign was eventually wicked and lit on fire.

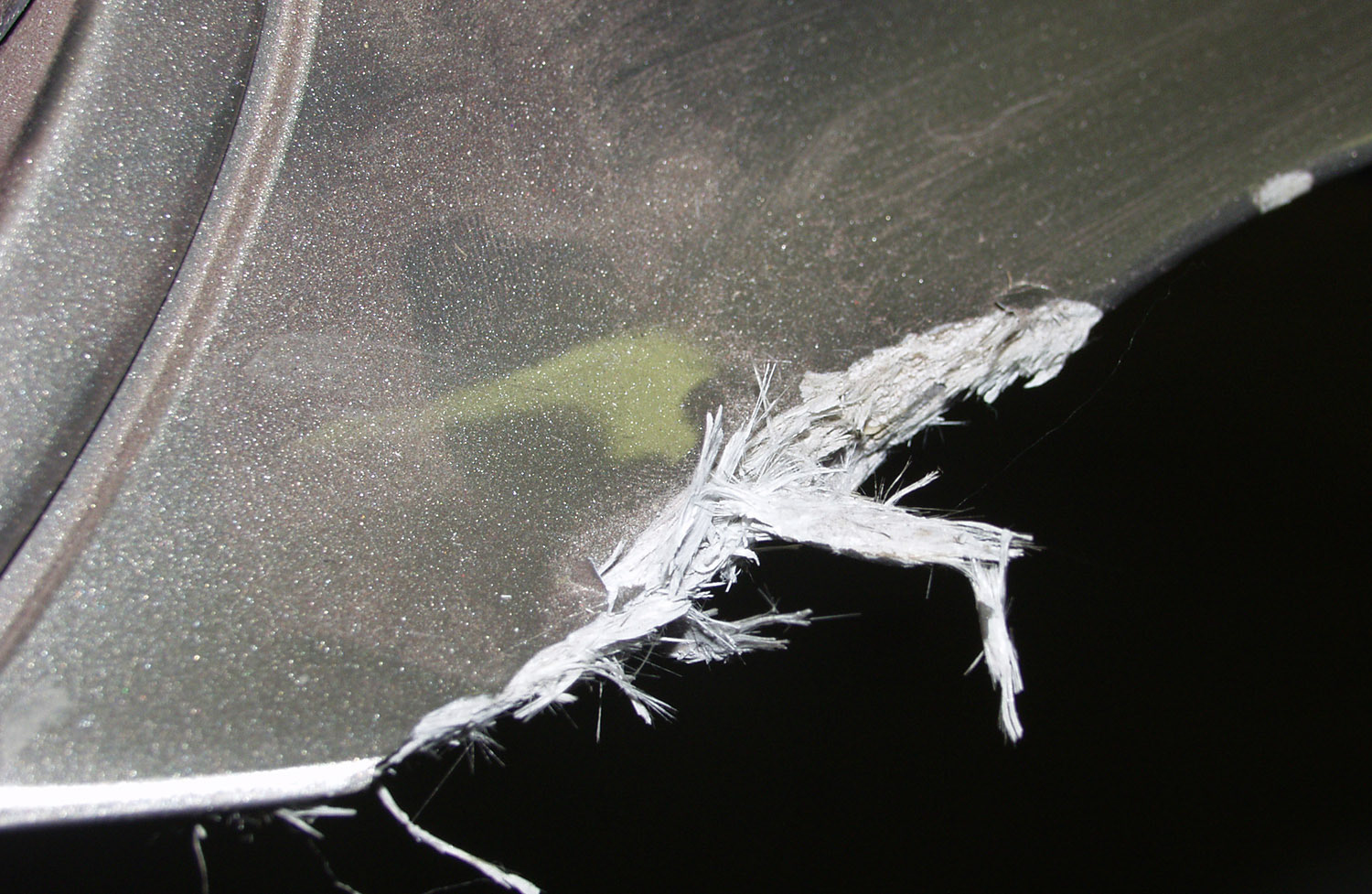

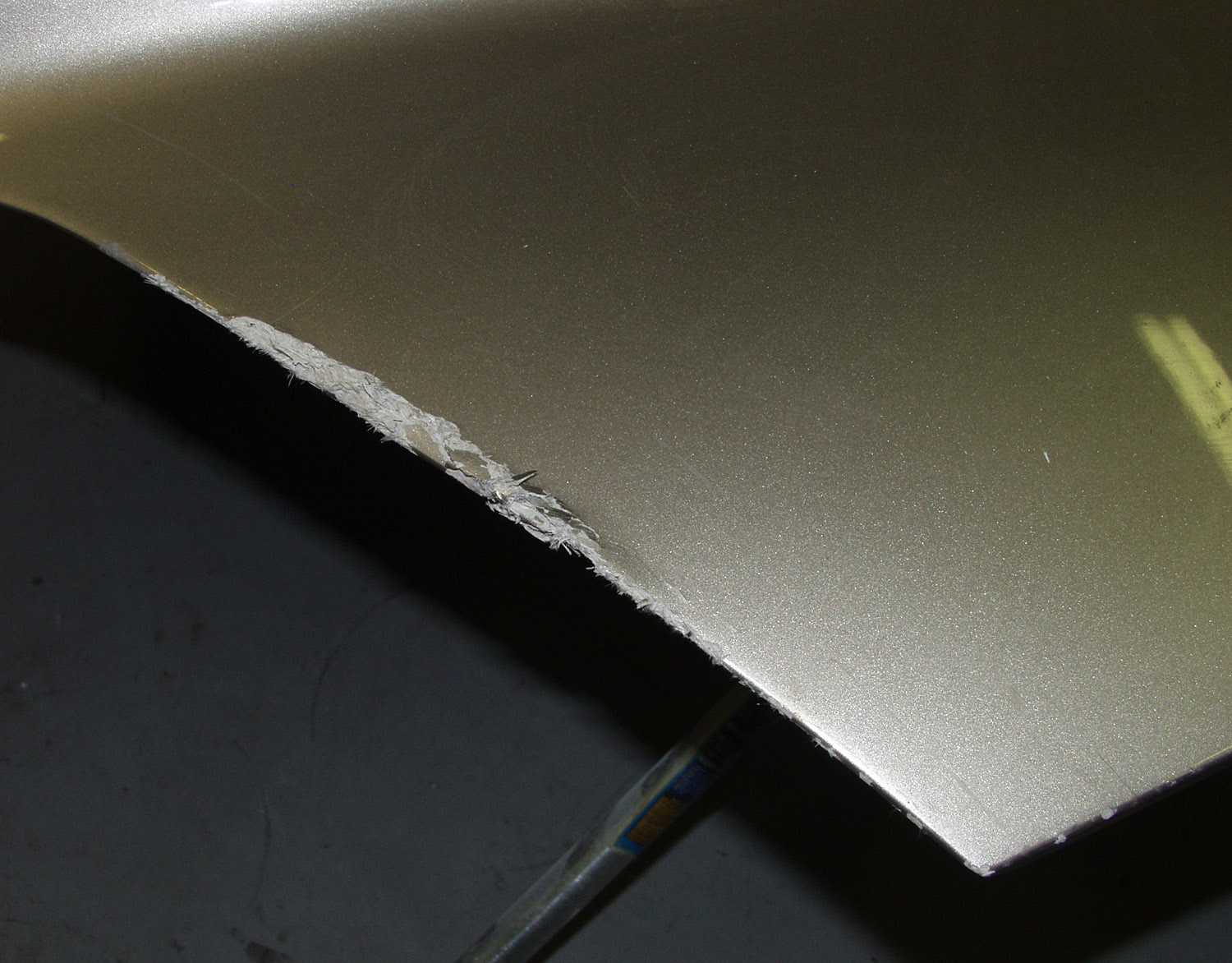

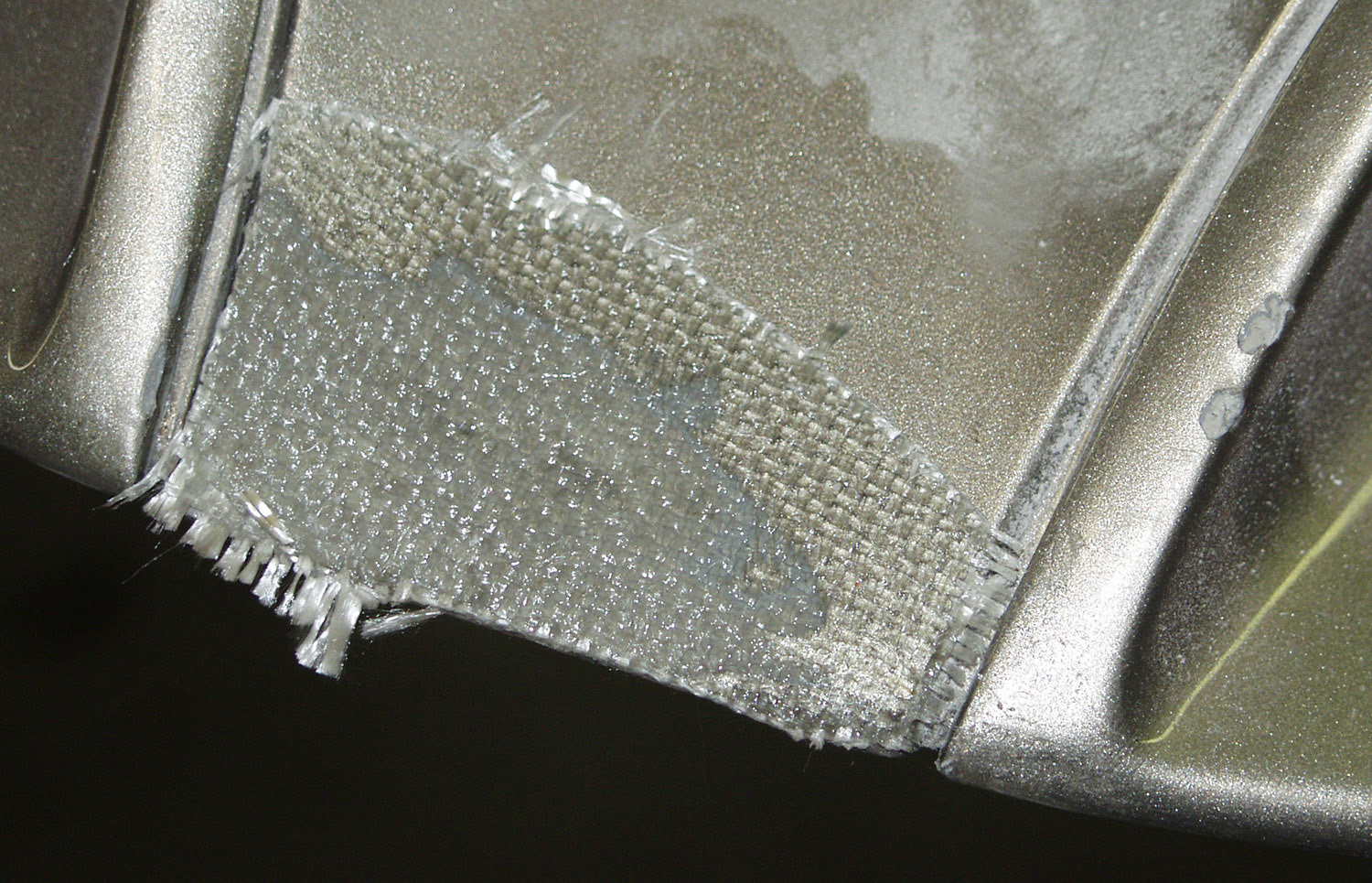

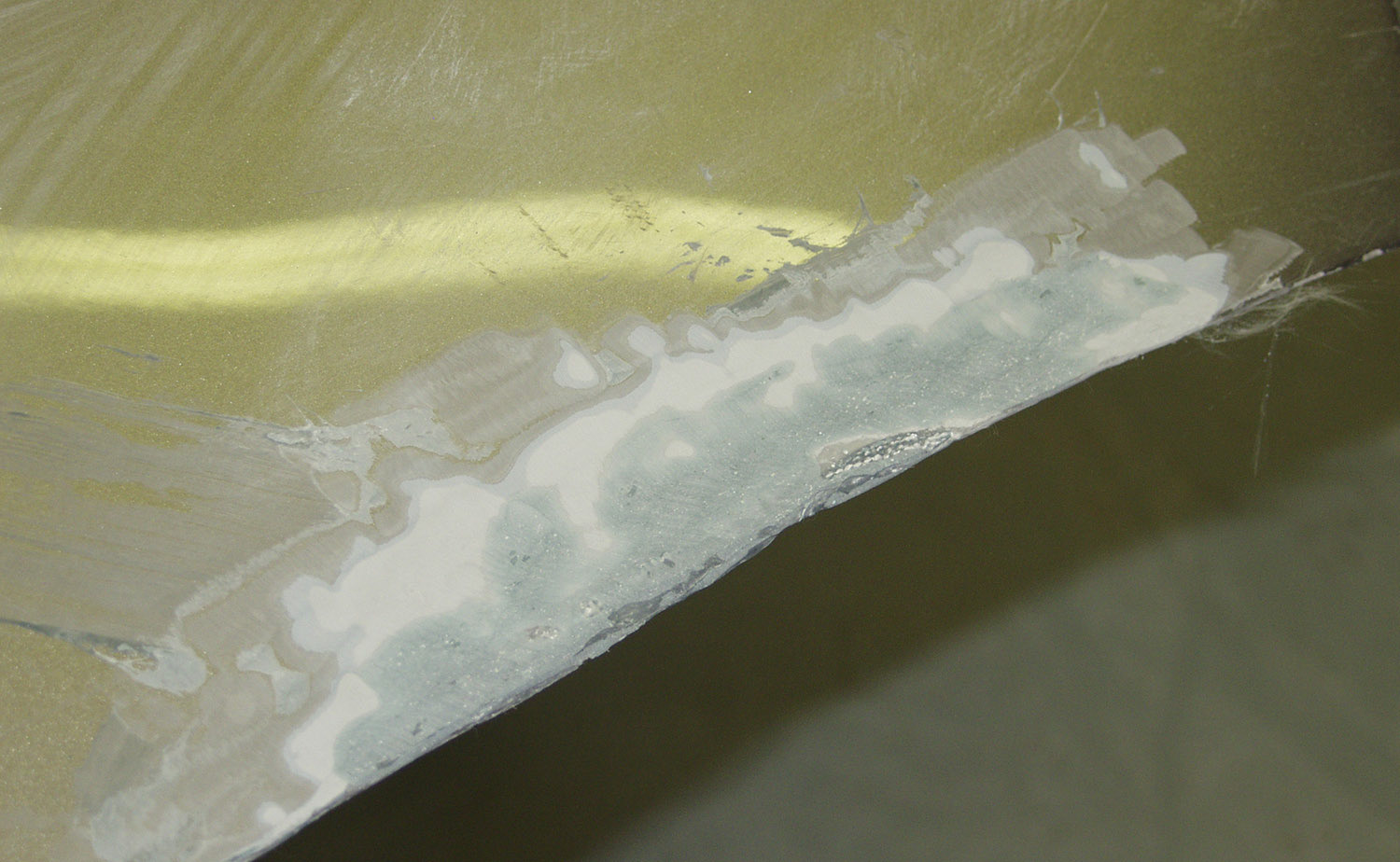

I ran across these old photos where I was doing some fiberglass repair on a salvaged Firebird hood that I purchased for my car. I just through I would throw this in here in case someone wants to see some basic fiberglass repair.